Recommend Products

Contact Us

| Email: | sales@sanchangpump.com |

| Hotline: | +86 133 0748 1676 |

| +86 193 1300 1794 | |

| Mobile: | +86 133 0748 1676 |

| Wechat: | +86 193 1300 1794 |

| Address: | No.517,Xiangfu Road |

| Yuhua District, | |

| Changsha City | |

| Hunan Province, P.R.C |

IJ type corrosion resistant chemical centrifugal pump

Classification:

Petrochemical industry

OH1/OH2 Chemical pump

IJ type corrosion resistant chemical centrifugal pump

Metallurgical industry

Energy saving transformation

Key words:

water pump

Head range: 5~80m

Conveying temperature:-80 ℃ ~ 450 ℃

Inlet pressure: 16~250m

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

Hotline:

- Product Description

- Performance Parameter

- Installation Drawings

- Installation And Use

- Faults And Solutions

-

- Commodity name: IJ type corrosion resistant chemical centrifugal pump

Flow range: 6~1200 m3/h<br>Head range: 5~80m<br>Conveying temperature:-80 ℃ ~ 450 ℃<br>Inlet pressure: 16~250m<br>Sealing form: packing seal, mechanical seal<br>Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc</br></br></br></br></br>

IJ type single-stage single-suction cantilever chemical centrifugal pump is a new product optimized and designed on the basis of IH series pumps, referring to foreign technologies and combining with actual use by users. Its rated performance and installation size meet ISO2858 standards, which are equivalent to ISO2858-1975, and its manufacturing technical conditions meet ISO5199 standards. It is mainly applicable to the transportation of slurry with solid content less than 50% and medium containing crystalline impurities in chemical process flow, it belongs to the same type as the IH type promoted by the state.

Rotation direction

Viewing from the drive end, rotate clockwise and turn opposite to the F-type system.

Main use

Soda industry: ammonia brine mother liquor produced by soda ash and ammonia, normal temperature caustic soda produced by chlor-alkali, chlorine products and chlorate, hypochlorite.

Non-ferrous metallurgy: electrolyte for electrolytic copper fetters, acid mist for drilling, ore slurry for zinc production, hunger acid for hunger production, and transportation of acid and sulfur service for gold production.

Iron and steel industry: electroplating, pickling, waste acid treatment.

Acid industry: nitric acid, sulfuric acid, hydrochloric acid, phosphoric acid, acetic acid, etc.

Petrochemical: petroleum refining acetaldehyde, alkyl benzene manufacturing.

Synthetic fiber and plastics industry: polyester, PVC production, textile, printing and dyeing industry.

Paper industry: delivery of pulp cooking liquor and bleaching liquor.

Fertilizer industry: urea, nitrate plating production.

Pharmaceutical industry: Production of pharmaceuticals and pesticides.

Environmental protection: acid mist liquid delivery.

Compared with IH pump, IJ chemical pump structure has the following characteristics;

1. The cantilever of the impeller is shortened and the diameter of the shaft is thickened;

2. Non-symmetric cross-section volute and pump casing without mouth ring;

3. Adopt three imported bearings;

4. Equipped with a new type of seal similar to the foreign advanced double-end mechanical seal or packing seal.

Because of the above structure, the pump has the following advantages

1, can transport high viscosity or solid medium, then the efficiency of the pump is higher than IH pump;

2. The asymmetrical cross-section volute reduces the impact loss of the fluid and shortens the size of the pump casing;

3. Increase the strength of the shaft and reduce the deflection of the rotor, so the operation is stable and the sealing life is long;

4. The impeller nut and the impeller are integrated to improve the inlet condition of the pump and improve the anti-cavitation performance of the pump;

5. Advanced shaft seal form makes the sealing effect better and reduces the leakage of the pump;

6. The gap of the pump can be adjusted without disassembling the pump casing and impeller, which reduces the maintenance time and saves the maintenance cost.

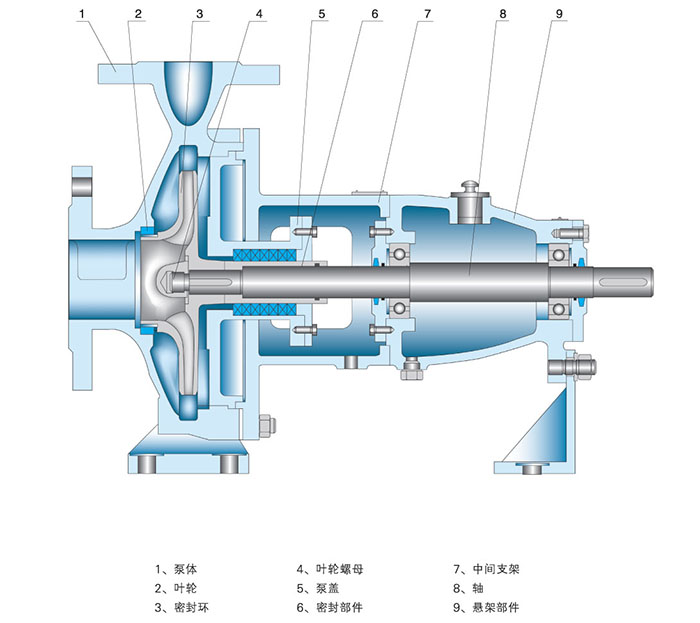

Structural features

The pump body is axial suction and radial discharge. The outlet and platinum are in a vertical plane, the pump body is cast with supporting feet, which are directly fixed on the base, and the pump cover is fixed on the suspension body through the upper opening. The pump body and the suspension body clamp the pump cover. During maintenance, remove the connecting nut between the suspension body and the pump body, and the rotating part of the pump can be withdrawn from the pump body without removing the inlet and outlet pipelines. This is an international general chemical pump structure. For large size pumps, an intermediate extension is added between the pump header and the motor shaft. This is during maintenance. Remove the middle extension section. The rotor part can exit the pump body and the motor does not have to move.

-

Flow range: 6~1200 m3/h

Head range: 5~80m

Conveying temperature:-80 ℃ ~ 450 ℃

Inlet pressure: 16~250m

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

-

-

1. Check whether the installation of the pump is reasonable, which has an important impact on the normal operation and service life of the chemical pump, and it needs to be corrected before installation.

2. It is necessary to ensure that the pump cannot be higher than the allowable NPSH when working. The water absorption height of the chemical pump needs to be determined according to the NPSH characteristics of the pump.

3. The suction and discharge pipelines should be additionally provided with brackets, which cannot be supported by the pump body.

4. The place where the pump is installed should be convenient for inspection and maintenance.

5. Installation sequence:

① Place the unit on the foundation with anchor bolts, and place a pair of wedge pads between the base and the foundation for correction.

② Loosen the coupling, place the level gauge on the pump shaft or the base respectively, use the adjustment wedge pad to find the level of the unit, and tighten the anchor bolts to avoid walking.

③ Concrete can be used to pour the anchor bolt hole and the base.

After the concrete is dry, tighten the anchor bolts and recheck the levelness of the pump shaft.

⑤ After connecting the pipeline and determining the rotation direction of the motor, connect the coupling again, review the concentricity of the shaft, measure the difference between the upper, lower, left and right of the outer circle of the coupling not to exceed 0.1mm, and the larger and smaller gaps between the end faces of the two couplings within a week cannot be higher than 0.3mm.

⑥ when the actual operation of the pump 3 hours to 4 hours after the inspection, if there is no bad situation on the installation of qualified.

-

Causes and Solutions of 1. Pump Not Producing Liquid in Operation

(1) Insufficient liquid in the pump chamber (the gas in the pump is not exhausted). Solution: re add liquid, pump cavity filled with liquid.

(2) Whether the pump operation and steering are correct when the equipment is started. Solution: check the supporting motor running direction.

(3) The speed of the pump is low after starting. Solution: stop to check the motor speed, replace the corresponding speed motor power.

(4) The filter screen at the inlet end is blocked. Solution: check the filter, remove debris, etc.

(5) The suction height is greater than the actual suction height of the pump, and the suction tank is vacuum. Solution: Reduce the suction height and check the pressure of the suction tank.

Causes and solutions of interruption after discharge of 2. pump

(1) Inlet pipeline leaks. Solution: check whether the inlet pipe connection and packing seal leakage.

(2) When filling the pump, the gas at the inlet end is not completely discharged. Solution: Require a refillable pump.

(3) The inlet end is blocked by foreign matter. Solution: stop the pump to deal with foreign matter.

(4) Intake a large amount of gas at the inlet. Solution: Check whether the suction port is vortex and whether the submerged depth is too shallow.

3. pump vibration causes and solutions

(1) the pump axis and the motor axis error is large. Solution: Readjust the position of the two axes.

(2) The suction height is too large, resulting in cavitation. Solution: Reduce the installation height.

(3) there is a phenomenon of mechanical friction. Solution: check where wear, maintenance.

Previous Page

Next Page

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!