Recommend Products

Contact Us

| Email: | sales@sanchangpump.com |

| Hotline: | +86 133 0748 1676 |

| +86 193 1300 1794 | |

| Mobile: | +86 133 0748 1676 |

| Wechat: | +86 193 1300 1794 |

| Address: | No.517,Xiangfu Road |

| Yuhua District, | |

| Changsha City | |

| Hunan Province, P.R.C |

AY BB2 API 610 Process Centrifugal Pumps Heavy Duty

Classification:

Single-stage End Suction Pump

AY horizontal single-stage centrifugal oil pump

Petrochemical industry

BB2 Pump

AY horizontal single-stage centrifugal oil pump

Key words:

water pump

Head: H = 30~330m

Temperature: T =-45~420 ℃

Hotline:

- Product Description

- Performance Parameter

- Installation Drawings

- Installation And Use

- Faults And Solutions

-

- Commodity name: AY BB2 API 610 Process Centrifugal Pumps Heavy Duty

Flow: Q = 2.5~800 m3/h<br>Head: H = 30~330m<br>Temperature: T =-45~420 ℃</br></br>

Product Description

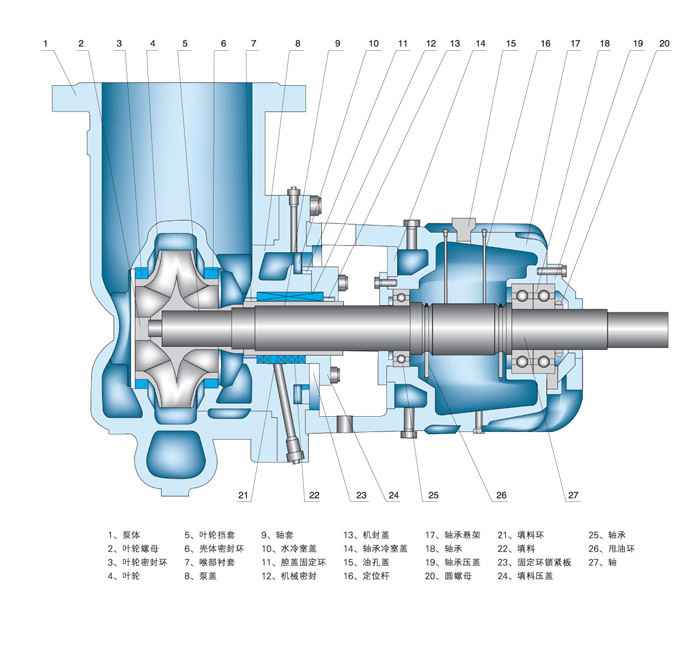

Our standard single-stage API 610 BB2 type pumps are center line-mounted, radially split, and feature a double-suction design with bearings located between the suction and discharge ends.

These pumps and their motors are flexibly coupled and mounted on a shared base plate.

The radial casing pull-out design allows for the removal of the rotor assembly without the need to disturb the driver, coupling hubs, or casing nozzle connections

API 610 BB2 series heavy duty centrifugal process pumps

Product profiles:

- BB2 series heavy-duty chemical process pumps are horizontal, radially split, supported at both ends, and centerline mounted centrifugal pumps.

- They are designed to meet demanding working conditions and can be divided into single-stage, two-stage, and three-stage structures.

- They are highly efficient, energy-saving, highly reliable, high temperature resistant, and high pressure resistant.

- They are widely used in oil refining, petrochemicals, and other industries to transport high-temperature, high-pressure, or corrosive liquids.

Features:

- Between bearings, centerline mounted, minimize displacement by heat expansion and cold contraction.

- Double volute, dynamically balanced, self-venting design.

- Top suction and top discharge, full access case cover for both ends.

- Shaft designed working in tensile stress preventing rotors play.

- API 682 seal chamber accommodates multiple seal types and pipe plan.

- Radially split casing with spacer coupling, replacement to impeller, seal or bearing without dismounting pump casing.

Applications:

- High pressure application.

- Sour water.

- Propane.

- Light hydrocarbons.

- Hot and corrosive naphthenic crude oil.

- Hot sandy crude oil.

- Vacuum bottoms.

- Refining.

- Petrochemical.

- Gas processing.

- Synfuels.

- Offshore.

-

Flow: Q = 2.5~800 m3/h

Head: H = 30~330m

Temperature: T =-45~420 ℃

-

-

1. Installation Instructions

1. The installation and correction work must be carried out carefully and must not be done hastily, because the quality of the pump installation has an important impact on the smooth operation and service life of the pump.

2. The installation height, length and pipe diameter of the pump suction pipe should meet the calculated value, strive to be short, reduce unnecessary losses, and ensure that the pump does not exceed its allowable NPSH when working.

3. The suction and discharge pipelines should have brackets, and the pump is not allowed to bear the load of the pipeline.

4. The place where the pump is installed should be spacious enough to facilitate the maintenance work.

2. installation sequence

1. Place the unit on the foundation with buried anchor bolts, and use pairs of wedge pads between the base and the foundation to correct the level.

2. Loosen the coupling, place a level on the pump shaft and the base respectively, adjust the level of the unit by adjusting the wedge pad, and tighten the anchor bolts appropriately to prevent walking.

3. Correct the concentricity of the pump shaft and the motor shaft, allowing the deviation of the plane clearance of the coupling to be 0.1mm, ensuring that the clearance is uniform, and the tolerance is 0.3mm.

4. After connecting the pipeline and determining the rotation direction of the motor, connect the coupling and check the concentricity of the shaft again.

5. After 2~3 hours of actual trial operation of the unit, make a final inspection. If there is no bad phenomenon, the installation is considered qualified. Check bearing temperature and vibration during commissioning.

6. During the installation process, in order to prevent debris from falling into the machine, all holes of the unit should be covered.

7. In order to prevent debris in the pipeline from entering the pump, a filter should be installed in the pump glue for the newly installed pipeline, and its effective cross section should be 2 to 3 times greater than the cross section of the suction pipe.

-

1. The pump cannot be started or the starting load is large

(1) The prime mover or power supply is not normal.

Processing method: is to check the power supply and prime mover.

(2) The pump is stuck.

Treatment method: check the coupling by hand and disassemble it if necessary to eliminate the fault of dynamic and static parts.

(3) the packing is too tight.

Treatment method: is to relax the filler.

(4) The discharge valve is not closed.

Treatment method: is to close the discharge valve, restart.

(5) the balance pipe is not smooth.

Treatment method: dredge the balance pipe.

2. The pump cannot discharge liquid

(1) The filling pump is insufficient (or the gas in the pump is not exhausted).

Treatment method: It is to refill the pump.

(2) pump steering is wrong.

Processing method: is to check the direction of rotation.

(3) pump speed is too low.

Treatment method: check the speed and increase the speed.

(4) The filter screen is blocked and the bottom valve is ineffective.

Treatment method: check the filter screen to eliminate debris.

(5) suction height is too high, or suction tank vacuum.

Treatment method: reduce the suction height; Check the pressure of the suction tank.

3. The pump is interrupted after discharging liquid

(1) Air leakage in the suction line.

Treatment method: is to check the suction side pipe connection and stuffing box sealing.

(2) When filling the pump, the gas on the suction side is not completely discharged.

Treatment method: It is required to recharge the pump.

(3) The suction side is suddenly blocked by foreign matter.

Treatment method: stop the pump to deal with foreign matter.

(4) Inhale a large amount of gas.

Treatment method: check whether there is vortex in the suction port and whether the submerged depth is too shallow.

4. Insufficient flow

(1) Same as B and C.

Treatment method: is to take corresponding measures.

(2) The static head of the system increases.

Treatment method: check the liquid height and system pressure.

(3) Increased resistance loss.

Treatment method: check the pipeline and check valve and other obstacles.

(4) the casing and impeller wear ring wear is too large.

Treatment method: is to replace or repair the wear ring and impeller.

(5) Leakage from other parts.

Treatment method: check the shaft seal and other parts.

(6) pump impeller blockage, wear, corrosion.

Treatment method: cleaning, inspection, exchange.

5, the lift is not enough

(1) Same as (1),(2),(3),(4) of B, (1) of c, (6) of d.

Treatment method: is to take corresponding measures.

(2) the impeller installed reverse (double suction wheel).

Treatment method: is to check the impeller.

(3) The density and viscosity of the liquid are inconsistent with the design conditions.

Treatment method: is to check the physical properties of the liquid.

(4) The flow rate is too large during operation.

Treatment method: is to reduce traffic.

6. Power consumption in operation

(1) There is friction between impeller and wear ring, impeller and shell.

Treatment method: is to check and repair.

(2) Same as item (4) of e.

Treatment method: is to reduce traffic.

(3) The liquid density increases.

Treatment method: check the liquid density.

(4) the packing is too tight or dry friction.

Treatment method: is to loosen the packing, check the water seal pipe.

(5) bearing damage.

Treatment method: is to check and repair or replace the bearing.

(6) the speed is too high.

Processing method: is to check the drive machine and power supply.

(7) The pump shaft is bent.

Processing method: is to correct the pump shaft.

(8) The axial force balance device failed.

Treatment method: check the balance hole and whether the return pipe is blocked.

(9) poor coupling alignment or axial clearance is too small.

Treatment method: check the alignment and adjust the axial clearance.

7. Pump vibration or abnormal sound

(1) Same as items (4) of C and (5),(7) and (9) of F.

Treatment method: is to take corresponding measures.

(2) The vibration frequency is 0 ~ 40% of the working speed. Excessive bearing clearance, loose bearing, impurities in the oil, poor oil quality (viscosity, temperature), foaming of oil due to air or process liquid, poor lubrication, and bearing damage.

Treatment method: After inspection, take corresponding measures, such as adjusting the bearing clearance, removing impurities in the oil, and replacing the new oil.

(3) The vibration frequency is 60% ~ 100 working speed. The bearing problem is the same as (2), or the seal gap is too large, the retainer is loose, and the seal is worn.

Treatment method: check, adjust or replace the seal.

(4) The vibration frequency is 2 times the working speed. Misalignment, coupling looseness, seal friction, shell deformation, bearing damage, bearing resonance, thrust bearing damage, shaft bending, poor fit.

Treatment method: check, take corresponding measures, repair, adjust or replace.

(5) The vibration frequency is n times the working speed. Pressure pulsation, non-central, shell deformation, seal friction, support or foundation resonance, pipeline, machine resonance.

Treatment method: is the same as (4), strengthen the foundation or pipeline.

(6) The vibration frequency is very high. Shaft friction, seals, bearings, inaccuracy, bearing jitter, poor shrink fit, etc.

Treatment method: the same as (4).

8. Bearing heating

(1) The scraping of bearing pads is not required.

Treatment method: is to repair the bearing pad or replace.

(2) bearing clearance is too small.

Treatment method: is to readjust the bearing clearance or scraping.

(3) Insufficient amount of lubricating oil and poor oil quality.

Treatment method: increase the amount of oil or replace the lubricating oil.

(4) poor bearing assembly.

Treatment method: check the bearing assembly according to the requirements and eliminate the unsatisfactory factors.

(5) cooling water circuit.

Treatment method: check and repair.

(6) bearing wear or loose.

Treatment method: is to repair the bearing or scrap. If loose, re-tighten the relevant bolts.

(7) The pump shaft is bent.

Processing method: is to correct the pump shaft.

(8) The oil slinger is deformed, the oil slinger cannot rotate, and it cannot be oiled.

Treatment method: it is to update the oil slinger.

(9) poor coupling alignment or axial clearance is too small.

Treatment method: check the alignment and adjust the axial clearance.

9. Shaft seal heating

(1) the packing is too tight or friction.

Treatment method: is to loosen the packing, check the water seal pipe.

(2) The water seal ring is misaligned with the water seal pipe.

Processing method: is to re-check the alignment.

(3) Flushing and cooling are good.

Treatment method: check the flushing cooling circulation pipe.

(4) mechanical seal failure.

Treatment method: check the mechanical seal.

10. Large rotor movement

(1) Improper operation, and the operating conditions are far away from the design conditions of the pump.

Treatment method: strict operation, so that the pump is always running near the design conditions.

(2) the balance is not smooth.

Treatment method: dredge the balance pipe.

(3) The material of the balance plate and the balance plate seat does not meet the requirements.

Treatment method: replace the balance plate and balance plate seat with the required material.

11. Water hammer

(1) Due to a sudden power failure, the system pressure fluctuates, and the negative pressure of the discharge system appears. The bubbles dissolved in the liquid escape to cause gas in the pump or pipeline.

Treatment method: the gas is discharged.

(2) the high pressure liquid column due to sudden power outage rapid backflow, impact on the pump outlet check valve valve plate.

Treatment method: It is to transform the layout of the pipeline and pipeline accessories of the unreasonable discharge system of the pump.

(3) The valve of the outlet pipeline closes too fast.

Treatment method: is slowly close the valve.

Previous Page

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!