Recommend Products

Contact Us

| Email: | sales@sanchangpump.com |

| Hotline: | +86 133 0748 1676 |

| +86 193 1300 1794 | |

| Mobile: | +86 133 0748 1676 |

| Wechat: | +86 193 1300 1794 |

| Address: | No.517,Xiangfu Road |

| Yuhua District, | |

| Changsha City | |

| Hunan Province, P.R.C |

IR horizontal single-stage single-suction hot water pump

Classification:

Single-stage End Suction Pump

IS horizontal single-stage single-suction centrifugal pump

Water conservancy industry

Hot water pump

IR horizontal single-stage single-suction hot water pump

Key words:

water pump

Head range: H = 5~125m

Conveying temperature:<120 ℃

Inlet pressure: ≤ 1 MPa (above 1.0 MPa, please declare)

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

Hotline:

- Product Description

- Performance Parameter

- Installation Drawings

- Installation And Use

- Faults And Solutions

-

- Commodity name: IR horizontal single-stage single-suction hot water pump

Flow range: Q = 5.6~720 m3/h<br>Head range: H = 5~125m<br>Conveying temperature:<120 ℃<br>Inlet pressure: ≤ 1 MPa (above 1.0 MPa, please declare)<br>Sealing form: packing seal, mechanical seal<br>Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc</br></br></br></br></br>

Product Description

IR type pump is a horizontal single-stage single-suction water centrifugal pump, used for industrial and agricultural and urban, drainage, fire water supply, etc., the temperature is not higher than 120 ℃.

Overview

IR(IS) type pump is designed according to the performance and size specified in international standard IS02858. Its technical standards are close to international standards and reach the international advanced level. It is one of the energy-saving pump products promoted in China.

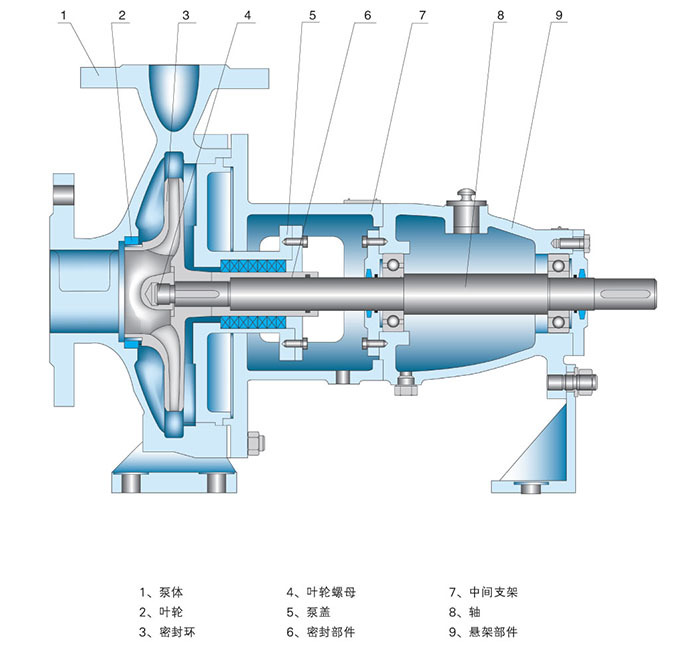

Structure Description

The pump has simple structure, reliable performance, small size, light weight, good cavitation resistance, low power consumption, and convenient use and maintenance.

The pump body and the cover part of the IR hot water single-stage pump are split from the back of the impeller, which is commonly referred to as the rear door opening structure. Its advantage is that it is convenient for maintenance. The pump body, suction pipeline, discharge pipeline and motor are not moved during maintenance. Only the intermediate coupling of the extension coupling is removed to exit the rotor parts for maintenance.

The casing of the pump (I. e., the pump body and the pump cover) constitutes the rotor of the pump's working chamber, impeller, shaft and rolling bearing. The suspension bearing part supports the rotor part of the pump, and the rolling bearing receives the radial and axial forces of the pump.

In order to balance the axial force of the pump, most of the pump impeller before and after are equipped with a sealing ring, and in the impeller back cover plate with a balance hole, because some pump axial force is not large, the impeller back without a sealing ring and balance hole.

The axial seal ring of the pump is composed of packing gland (9), packing ring (10), and packing (11) to prevent air intake or large amount of water leakage. If the impeller of the pump is balanced, the cavity equipped with soft packing is connected with the suction port of the impeller. If the liquid at the inlet of the impeller is in a vacuum state, it is easy to enter the air along the surface of the shaft sleeve. Therefore, a packing ring is installed in the packing cavity. Through the small hole on the pump cover, the pressure water in the pump chamber is led to the filling ring for sealing. If the impeller of the pump does not have a balance hole, the liquid pressure on the back of the impeller is greater than atmospheric pressure, so there is no problem of steam leakage, so the packing ring may not be installed.

In order to avoid damage to the shaft, a shaft sleeve is installed at the part where the shaft passes through the filling cavity for protection, and an O-shaped seal is installed between the shaft sleeve and the shaft to prevent air intake or water leakage along the mating surface.

The transmission mode of the pump is connected with the motor by extending the elastic coupling. The direction of rotation of the pump, viewed from the drive end, is clockwise.

Model Description

IR100-80-160A

IR-horizontal single-stage single-suction centrifugal pump

100-Pump inlet diameter 100mm

80-Pump outlet diameter 80mm

160-Nominal dimensions of pump impeller

A- impeller cutting code (B, C, etc. in turn)

-

Flow range: Q = 5.6~720 m3/h

Head range: H = 5~125m

Conveying temperature:<120 ℃

Inlet pressure: ≤ 1 MPa (above 1.0 MPa, please declare)

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

-

-

1. assembly and disassembly

Before assembling, the pump shall first check whether there are any defects affecting the assembly and scrub them clean before assembling.

1. The connecting bolts and plug can be tightened on the corresponding parts in advance.

2. The O-shaped sealing ring, paper pad, felt, etc. can be placed on the corresponding parts in advance.

3. The sealing ring and packing, packing ring and packing gland can be installed in the pump cover in turn.

4. Install the rolling bearing on the shaft, then install it in the suspension, close the gland, press the rolling bearing, and put the connecting bolt on the shaft.

5. Install the shaft sleeve on the shaft, then install the pump cover on the suspension, and then surround the impeller and stop pad. Install and tighten the impeller nut, etc. Finally, install the above components into the pump body, and tighten the connecting bolts on the pump body and the pump cover.

In the above assembly process, some small parts such as flat key, oil stop pan, O-shaped seal ring in the shaft sleeve of water stop, etc. are easy to leak or the order of clamping, so special attention should be paid.

The pump disassembly sequence can basically be the reverse of the assembly sequence.

2. installation

The quality of the pump installation has no important influence on the operation and life of the pump, so the installation and calibration must be carried out carefully. Appearance and installation dimensions of the pump.

1. Installation and calibration:

1) Remove the greasy and dirt on the base and put the base on the foundation.

2) Check the levelness of the base with a level gauge, and allow leveling with wedge iron.

3) Pour the base and anchor bolt holes with cement.

4) After the cement is dry, check whether the holes of the base and anchor bolts are loose, tighten the anchor bolts after they are appropriate, and check the levelness again.

5) Clean the support plane of the base, the plane of the pump foot and the motor foot, and install the water recorder and the motor on the base.

6) A certain gap should be maintained between the couplings. Check whether the center line of the water pump shaft and the motor shaft is consistent.

The difference between the left and right sides of the outer circle of the measuring coupling shall not exceed 0.1mm, and the difference between the largest and smallest sides of the gap between the end faces of the two couplings shall not exceed 0.3(mm

2. Installation instructions:

1) the installation height of the centrifugal pump, the length of the pipeline. Diameter, flow rate should be in line with the calculation, and strive to reduce unnecessary losses.

2) large pipe diameter should be taken for long distance transportation. The pipeline of the pump should have its own bracket. The weight of the pipeline is not allowed to be added to the pump to avoid crushing the pump.

3) discharge pipeline such as installed check valve should be installed on the outside of the gate valve.

3. starting, stopping and running

1. Starting:

1) It should be determined whether the rotation direction of the motor is correct and the operation of the pump is flexible before the machine is connected.

2) Close the idle valve on the discharge pipeline.

3) Fill the pump with water, or use the vacuum pump to draw water.

4) Turn on the power supply. When the pump reaches the normal speed, gradually open the gate valve on the discharge pipe and adjust it to the required working condition. When the gate valve on the discharge pipe is closed, the continuous working time of the pump shall not exceed 3 minutes.

2. Stop:

1) Gradually close the gate valve on the discharge pipeline and cut off the power supply.

2) If the ambient temperature is lower than 0 ℃, the water in the pump should be released to avoid freezing and cracking.

3) If the long-term use, the pump should be disassembled, cleaned and oiled, packaged and kept.

3. Operation:

1). In the process of driving and running, must pay attention to observe the meter reading, bearing heat, packing leakage and heat and vibration and noise is normal, if found abnormal situation, should be dealt with immediately.

2). The bearing temperature shall not be higher than 80 ℃, and the bearing temperature shall not exceed 40 ℃ than the surrounding temperature.

3). Filler normal, water leakage should be a small amount of uniform.

4). Bearing oil level should be kept in the normal position, not too high or too low, too low should be timely supplement lubricating oil.

5). Such as the seal ring and the impeller with the part of the gap wear is too large should be replaced with a new seal ring.

-

Fault phenomenon

Cause of failure

Exclusion method

1. The water pump does not produce water

a. The inlet and outlet valves are not opened, the inlet and outlet pipelines are blocked, and the runner impeller is blocked.

B, the motor running direction is wrong, the motor phase loss speed is very slow.

C, suction pipe leakage.

D, the pump is not filled with liquid, there is air in the pump cavity.

E, the inlet water supply is insufficient, the suction is too high, the bottom valve leaks.

F, pipeline resistance is too large, pump selection is improper.

A, check, remove the blockage.

B, adjust the direction of the motor, tighten the motor wiring.

C, tighten the sealing surface, eliminate air leakage.

D, fill the liquid and open the exhaust valve, exhaust air.

E, shut down, check, adjust (grid water pipe or with suction range use prone to this phenomenon).

F, reduce the pipeline curve, re-select the pump.

2. Insufficient water pump flow

A, first press 1. reason inspection.

B, pipe, pump flow impeller part of the blockage, scale accumulation, valve opening is insufficient.

C, low voltage.

D, impeller wear.

A, first press 1. exclude.

B, remove the blockage, re-adjust the valve opening.

C, voltage stabilization.

d. Replace the impeller.

3. Excessive power

A, exceed the rated flow use.

B, suction is too high.

C, pump bearing wear.

A, adjust the flow, close the small outlet valve.

B. reduced.

c. Replace the bearing.

4. Vibration of noise

a. Unstable pipeline support.

B, liquid mixed with gas.

C, produce cavitation.

D, bearing damage.

E, motor overload heating operation.

a. Stabilize the pipeline.

B, increase the suction pressure exhaust.

C, reduce the vacuum degree.

d. Replace the bearing.

e. Adjust by 5.

5. Motor heating

A, excessive flow, overload operation.

B, touch.

C, motor bearing damage.

d. Insufficient voltage.

a. Close the outlet valve.

B. Check and exclude.

c. Replace the bearing.

d. Voltage stabilization.

6. Water leakage of water pump

A, mechanical seal wear.

B, the pump body has sand hole or rupture.

C, the sealing surface is not smooth.

d. Loose installation bolts.

a. replacement.

B, welding repair or replacement.

c. Finishing.

d. Fastening.

Next Page

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!