Recommend Products

Contact Us

| Email: | sales@sanchangpump.com |

| Hotline: | +86 133 0748 1676 |

| +86 193 1300 1794 | |

| Mobile: | +86 133 0748 1676 |

| Wechat: | +86 193 1300 1794 |

| Address: | No.517,Xiangfu Road |

| Yuhua District, | |

| Changsha City | |

| Hunan Province, P.R.C |

ZA type petrochemical process pump

Classification:

OH1/OH2 Chemical pump

ZA type petrochemical process pump

Petrochemical industry

Electric power industry

Urban water supply

Key words:

water pump

Head range: 16~250m

Conveying temperature:-80-450 ℃

Inlet pressure: 0-7.5MPa

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

Hotline:

- Product Description

- Performance Parameter

- Installation Drawings

- Installation And Use

- Faults And Solutions

-

- Commodity name: ZA type petrochemical process pump

Flow range: 5.5~2600 m3/h<br>Head range: 16~250m<br>Conveying temperature:-80-450 ℃<br>Inlet pressure: 0-7.5MPa<br>Sealing form: packing seal, mechanical seal<br>Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc</br></br></br></br></br>

ZA chemical process centrifugal pump is designed and produced according to API610 and VDMA24297 (light/medium) specifications. Can transport a variety of temperature and concentration of sulfuric acid, nitric acid, hydrochloric acid and phosphoric acid and other inorganic acid and organic acid solution; a variety of temperature and concentration of sodium hydroxide and sodium carbonate and other alkaline solution; a variety of salt solution; a variety of liquid petrochemical products, organic compounds and other corrosive liquid.

Model Description

Example: ZA25-200C

ZA-petrochemical process pump

25 -- Diameter of discharge outlet (mm)

200-nominal diameter of impeller (mm)

C- impeller cutting times, in order of A,B,C...

Scope of application

This type of pump is suitable for oil refineries, petrochemical industry, coal processing engineering, low temperature engineering, paper industry, sugar industry, water supply plant, seawater desalination plant, power plant, environmental protection engineering and shipbuilding industry. Seen from the motor end, the rotation direction of the pump is clockwise.

Material selection

Optional corrosion-resistant materials include 303, 305, 306, 307, 316, 316L, 904, 904L, 804, ECR alloy, NiCr alloy, Hastelloy, CD-4MnCu and titanium alloy, etc., which can meet the requirements of the above media. When ordering, please provide the details of the medium to be transported.

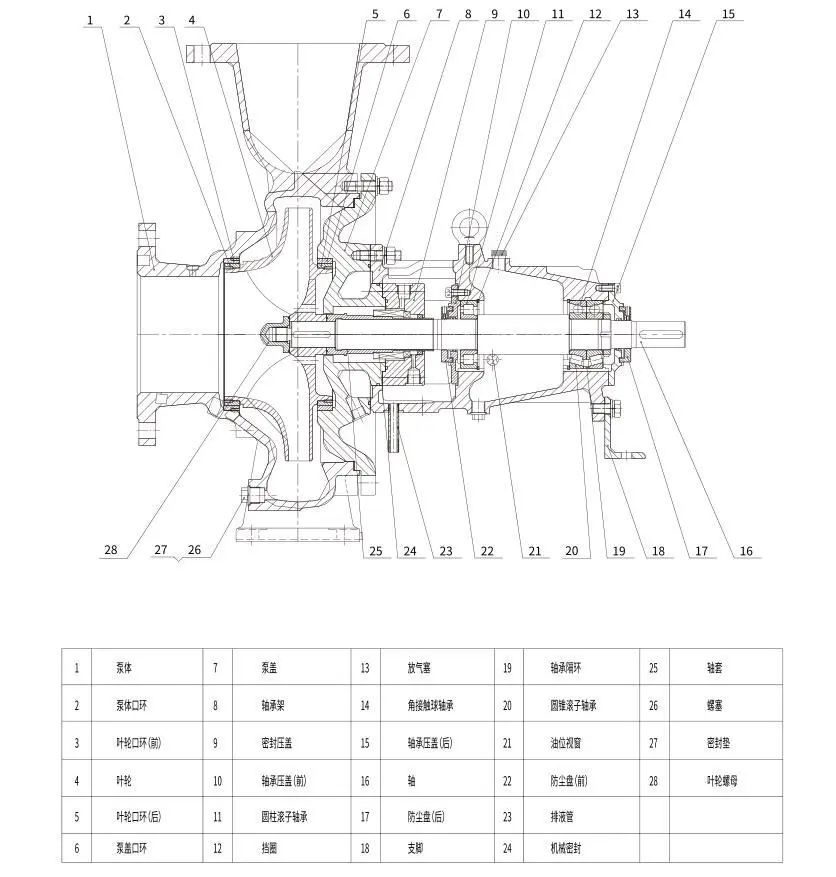

Structural features

1. This type of chemical process is designed according to API standard pipeline. Impeller can be closed, semi-open, open three. Can transport clean, containing particles, containing a small amount of gas medium. Can also transport high temperature, low temperature, strong corrosive medium. The impeller is provided with a balance hole and a corrosion-resistant ring to balance the axial force.

2. The pump body and the bearing frame are connected by the middle connecting section. According to different working conditions, the intermediate connecting section can be made of different materials to avoid serious corrosion of the bearing frame and bearing when conveying strong corrosive medium. At the same time, the middle connecting section is provided with a water-cooled cavity, which passes through the cooling circulating water to block the high temperature medium from transmitting the high temperature to the bearing.

3. The sealing form can adopt packing seal, single and double mechanical seal, and container type single mechanical seal. According to different situations and user requirements for cooling and flushing, sealing can be selected from the case according to API682 design specifications.

4. The bearing frame is designed with three forms: air-cooled heat sink, air-cooled fan and water-cooled cavity, which can be selected by users according to the working conditions.

The bearings are lubricated by oil rings splashed with thin oil from the oil tank. The oil in the oil tank is cooled by the water in the water cooling chamber, and the heat in the bearing is taken away by the cold water to ensure that the bearing is in normal working condition at any time.5. According to the medium temperature and pressure, the support form adopts the center support and the tripod support.

6. The rated pressure rating of the suction and discharge flanges is the same.

-

Flow range: 5.5~2600 m3/h

Head range: 16~250m

Conveying temperature:-80-450 ℃

Inlet pressure: 0-7.5MPa

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

-

-

Disassembly and assembly

(1) If the impeller is replaced or checked, the outlet valve can be closed, the flange connecting bolts and the bottom plate connecting bolts can be removed, and the pump can be lifted out of the container with a lifting tool.

(2) hang the bottom plate on the bracket, remove all the bolts of the pump body, take out the pump cover and impeller nut, and tap the pump body with a double hammer to remove the impeller.

(3) for the replacement of rolling bearings or packing, the bottom plate does not move, as long as the motor and the corresponding bracket, remove the pump coupling, gland, round nut, take out the bearing body. To replace the packing, first remove the packing gland, then remove and replace the packing.

(4) The order of assembly and disassembly NB,0 is opposite, and the concentricity of the accessories on the shaft must be paid attention.

Installation, use and maintenance

1. After the pump is assembled, turn the coupling to see if it rotates flexibly. Check whether there is metal friction sound and whether the nuts of each component are tightened.

2. Check the concentricity of the pump shaft and the motor shaft. The left and right difference of the outer circle of the two couplings shall not exceed 0.1mm, and the gap between the end faces of the two couplings shall be kept at 1~2.5mm.

3. The distance between the suction population of the pump and the bottom of the container is 2 to 3 times the suction caliber, and the distance between the pump body and the container wall is greater than 2,5 times the caliber.

4. The outlet pipe of the pump shall be supported by another bracket, and its weight is not allowed to be supported on the pump.

5. Check the rotation direction of the motor to make the rotation direction of the pump conform to the indicated direction.

6. Close the gate valve and pressure gauge on the outlet pipeline and connect the cooling water pipe.

7. Start the motor, open the pressure gauge, slowly open the gate valve of the outlet pipe to the required position, and put the person into normal operation.

8, often check the pump and motor, bearing temperature rise should not exceed 75 ℃, bearing box should add enough butter.

-

1. pump does not start

1, power failure: should check the power switch and wiring.

2, motor wiring failure: should check the motor connection.

Internal blockage of the pump: check whether there is foreign matter in the pump.

4. Motor failure: check whether the motor is damaged.

Water output of 2. pump decreases

1, pump drum cavity leakage: should check the shaft seal, sealing ring and valve is damaged.

2. Inlet valve leakage: check whether the valve sealing ring is damaged.

3. There are foreign bodies in the pump cavity or friction or blockage in the pump: check whether there are foreign bodies in the pump and clean up the deposits in the pump.

Excessive noise during operation of 3. pump

1. The pump chassis is not in close contact with the bracket: the bracket should be reinstalled or replaced.

2. The contact between the pump drum cavity and the pump body is not close: the axial clearance should be adjusted to ensure close contact.

3, bearing damage or foreign matter into: the bearing should be replaced.

4. pump temperature rise

1, pump fire or burn out: should check whether the pump is damaged, replace the undamaged parts.

2, bearing damage or poor lubrication: should check the bearing and lubrication system, replace the bearing, strengthen lubrication.

The above are the common faults of submersible pumps and their solutions. Users should pay attention to regular maintenance and maintenance when using submersible pumps, and eliminate them in time according to specific faults. This can extend the service life of the submerged pump and ensure production safety.

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!