Recommend Products

Contact Us

| Email: | sales@sanchangpump.com |

| Hotline: | +86 133 0748 1676 |

| +86 193 1300 1794 | |

| Mobile: | +86 133 0748 1676 |

| Wechat: | +86 193 1300 1794 |

| Address: | No.517,Xiangfu Road |

| Yuhua District, | |

| Changsha City | |

| Hunan Province, P.R.C |

IH horizontal single-stage chemical centrifugal pump

Classification:

OH1/OH2 Chemical pump

IH horizontal single-stage chemical centrifugal pump

Petrochemical industry

Metallurgical industry

Key words:

water pump

Head range: 5~125m

Conveying temperature:-20-150 ℃ (please declare above 80 ℃)

Inlet pressure: 0-7.5MPa (above 0.4 MPa, please declare)

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD

Hotline:

- Product Description

- Performance Parameter

- Installation Drawings

- Installation And Use

- Faults And Solutions

-

- Commodity name: IH horizontal single-stage chemical centrifugal pump

Flow range: 6.3~400 m3/h<br>Head range: 5~125m<br>Conveying temperature:-20-150 ℃ (please declare above 80 ℃)<br>Inlet pressure: 0-7.5MPa (above 0.4 MPa, please declare)<br>Sealing form: packing seal, mechanical seal<br>Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD</br></br></br></br></br>

IH-type single-stage single-suction cantilever chemical centrifugal pump is to replace the F-type corrosion-resistant centrifugal water pump energy-saving, replacement products, the product is widely used in chemical, petroleum, metallurgy, paper, food, pharmaceutical, synthetic fiber and other industrial sectors, used to transport corrosive or do not allow pollution viscosity similar to water liquid. The inlet pressure of the pump shall not exceed 0.3MPa.

The temperature of the conveying medium is generally -20 ℃ ~ 105 ℃, and appropriate cooling measures can be taken when necessary to convey higher temperature liquids.

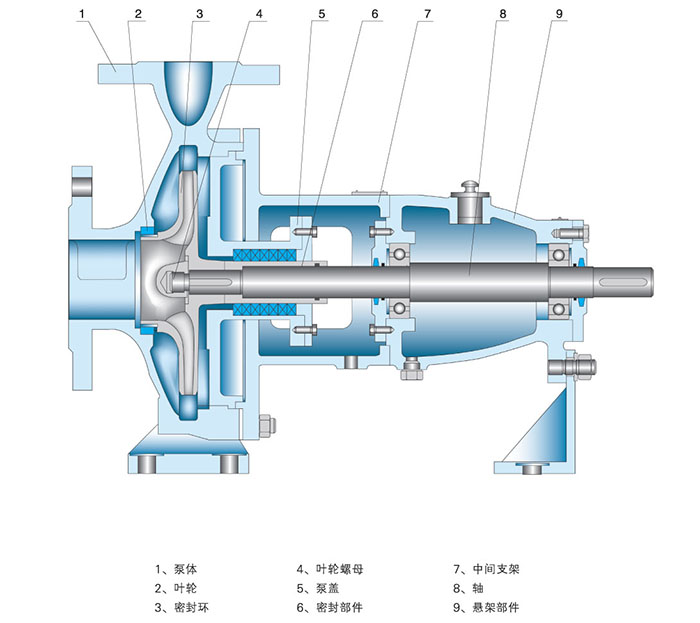

Structure Description

The main parts are pump body, impeller, sealing ring, impeller nut, pump cover, sealing parts, intermediate bracket, shaft and suspension, etc.

Structural features

The pump cover is fixed on the middle bracket through the stop, and then the pump cover is clamped in the middle through the connection between the pump body and the stop of the middle bracket. The pump body is axial suction, radial discharge, foot support type, can be directly fixed on the base. The suspension part is fixed on the middle bracket through the stop, and is supported on the base by the suspension bracket. During maintenance, the inlet and outlet connection pipes, pump body and motor can be removed, and the rotor components can be removed for maintenance only by removing the intermediate connection of the extension coupling.

The shaft seal has 9 forms of packing and mechanical seal, which can be selected according to the nature of the conveying medium and the requirements of the production process.

The pump is connected to the motor through an extended coupling, and the pump rotates clockwise when viewed from the drive end.

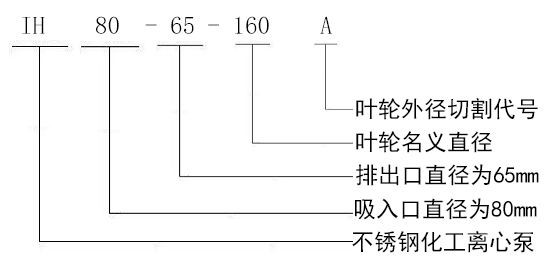

Model Description

Example: IH80-65-160A-304

IH-International Standard Chemical Pumps

80-80mm diameter of pump suction

65-Pump outlet diameter 65mm

160-Impeller nominal diameter 160mm

A- impeller outer diameter cutting code (A and B respectively represent the first and second cutting)

304-Material code of pump contact parts: ZG0Cr18Ni9

-

Flow range: 6.3~400 m3/h

Head range: 5~125m

Conveying temperature:-20-150 ℃ (please declare above 80 ℃)

Inlet pressure: 0-7.5MPa (above 0.4 MPa, please declare)

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD

-

-

Disassembly and assembly

(1) If the impeller is replaced or checked, the outlet valve can be closed, the flange connecting bolts and the bottom plate connecting bolts can be removed, and the pump can be lifted out of the container with a lifting tool.

(2) hang the bottom plate on the bracket, remove all the bolts of the pump body, take out the pump cover and impeller nut, and tap the pump body with a double hammer to remove the impeller.

(3) for the replacement of rolling bearings or packing, the bottom plate does not move, as long as the motor and the corresponding bracket, remove the pump coupling, gland, round nut, take out the bearing body. To replace the packing, first remove the packing gland, then remove and replace the packing.

(4) The order of assembly and disassembly NB,0 is opposite, and the concentricity of the accessories on the shaft must be paid attention.

Installation, use and maintenance

1. After the pump is assembled, turn the coupling to see if it rotates flexibly. Check whether there is metal friction sound and whether the nuts of each component are tightened.

2. Check the concentricity of the pump shaft and the motor shaft. The left and right difference of the outer circle of the two couplings shall not exceed 0.1mm, and the gap between the end faces of the two couplings shall be kept at 1~2.5mm.

3. The distance between the suction population of the pump and the bottom of the container is 2 to 3 times the suction caliber, and the distance between the pump body and the container wall is greater than 2,5 times the caliber.

4. The outlet pipe of the pump shall be supported by another bracket, and its weight is not allowed to be supported on the pump.

5. Check the rotation direction of the motor to make the rotation direction of the pump conform to the indicated direction.

6. Close the gate valve and pressure gauge on the outlet pipeline and connect the cooling water pipe.

7. Start the motor, open the pressure gauge, slowly open the gate valve of the outlet pipe to the required position, and put the person into normal operation.

8, often check the pump and motor, bearing temperature rise should not exceed 75 ℃, bearing box should add enough butter.

-

1. pump does not start

1, power failure: should check the power switch and wiring.

2, motor wiring failure: should check the motor connection.

Internal blockage of the pump: check whether there is foreign matter in the pump.

4. Motor failure: check whether the motor is damaged.

Water output of 2. pump decreases

1, pump drum cavity leakage: should check the shaft seal, sealing ring and valve is damaged.

2. Inlet valve leakage: check whether the valve sealing ring is damaged.

3. There are foreign bodies in the pump cavity or friction or blockage in the pump: check whether there are foreign bodies in the pump and clean up the deposits in the pump.

Excessive noise during operation of 3. pump

1. The pump chassis is not in close contact with the bracket: the bracket should be reinstalled or replaced.

2. The contact between the pump drum cavity and the pump body is not close: the axial clearance should be adjusted to ensure close contact.

3, bearing damage or foreign matter into: the bearing should be replaced.

4. pump temperature rise

1, pump fire or burn out: should check whether the pump is damaged, replace the undamaged parts.

2, bearing damage or poor lubrication: should check the bearing and lubrication system, replace the bearing, strengthen lubrication.

The above are the common faults of submersible pumps and their solutions. Users should pay attention to regular maintenance and maintenance when using submersible pumps, and eliminate them in time according to specific faults. This can extend the service life of the submerged pump and ensure production safety.

Previous Page

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!