Recommend Products

Contact Us

| Email: | sales@sanchangpump.com |

| Hotline: | +86 133 0748 1676 |

| +86 193 1300 1794 | |

| Mobile: | +86 133 0748 1676 |

| Wechat: | +86 193 1300 1794 |

| Address: | No.517,Xiangfu Road |

| Yuhua District, | |

| Changsha City | |

| Hunan Province, P.R.C |

FSB type fluoroplastic corrosion resistant pump

Classification:

OH1/OH2 Chemical pump

FSB type fluoroplastic corrosion resistant pump

Petrochemical industry

Metallurgical industry

Key words:

water pump

Head: 15~55m

Speed: 2900r/min

Power: 1.5 ~ 18.5KW

Inlet diameter: 25~100mm

Applicable temperature:-20 ℃ ~ 120 ℃

Inlet pressure: ≤ 0.3 MPa (above 0.3 MPa, please declare)

Sealing form: mechanical seal

Water pump material: fluorine plastic

Hotline:

- Product Description

- Performance Parameter

- Installation Drawings

- Installation And Use

- Faults And Solutions

-

- Commodity name: FSB type fluoroplastic corrosion resistant pump

Flow: 3.6~100 m3/h<br>Head: 15~55m<br>Speed: 2900r/min<br>Power: 1.5 ~ 18.5KW<br>Inlet diameter: 25~100mm<br>Applicable temperature:-20 ℃ ~ 120 ℃<br>Inlet pressure: ≤ 0.3 MPa (above 0.3 MPa, please declare)<br>Sealing form: mechanical seal<br>Water pump material: fluorine plastic</br></br></br></br></br></br></br></br>

Product Description

FSB type fluoroplastic corrosion-resistant pump is designed according to international standards. The pump body is lined with polyethylene glycol propylene (F46) in a metal shell. The pump cover, impeller and shaft sleeve are all covered with metal inserts and molded by integral sintering and pressing of fluoroplastic. The shaft seal is sealed with external bellows. The static ring is made of 99% alumina ceramic or silicon nitride. The moving ring is made of PTFE filling material, which is corrosion-resistant and wear resistant, it is suitable for transporting any concentration of sulfuric acid, hydrochloric acid, acetic acid, hydrofluoric acid, nitric acid, aqua regia, strong alkali, strong oxidant, organic solvent, reducing agent and other harsh conditions of strong corrosive medium. It is one of the strong corrosion resistant equipment in the world.

Overview

This series of pumps is a single-stage single-suction cantilever centrifugal pump, its structural features are: the flow components are made of fluorine plastic, the pump parts of the lining material with polyfluoroethylene propylene (F46) or polyvinylidene fluoride (F2) and other varieties, can be selected according to the needs of users.

This variety of pump is mainly suitable for conveying acid-base or solvent Lou clear medium. The use of special sealing, but also can transport a small amount of solid corrosive media. This series of pumps adopt WB2, 152, 169 and other forms of mechanical seal. The use temperature range is -20~100 ℃.

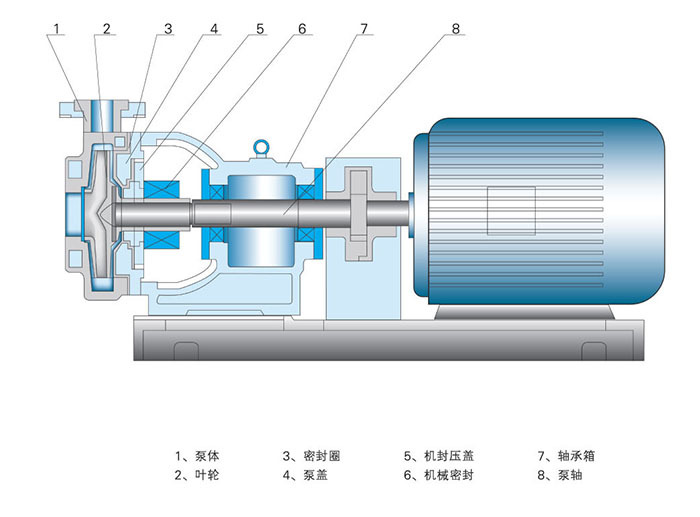

Structure Description

FSB-type fluoroplastic corrosion-resistant pump consists of pump body, impeller, cover, seal, bracket, pump shaft, side shaft, hanging bolt, nut and bottom plate.

1. Pump body: steel flange rings are embedded in the connecting parts on the left and right sides, each made of molded plastic synthetic gold.

2. A stainless steel (1 Cr18Ni9Ti) molded plastic alloy is buried in the right side of the cover.

3. Impeller: The connection method of connecting the shaft is adopted. The metal shaft is made of high-quality steel and covered with plastic synthetic gold after finishing. The impeller and the metal connecting shaft are firmly integrated to ensure that the shaft root and the rear part of the impeller bear the torque force when rotating, so that the wet part of the medium is plastic alloy.

4, mechanical seal: the use of WB2 type, ST type without cooling water adjustable end seal technology, made of silicon carbide, high purity alumina ceramic, filled with PTFE, graphite and other materials.

Use

It is suitable for conveying liquids in chemical, petroleum, pharmaceutical, pesticide, dye, paint, smelting, papermaking, electroplating, food, metallurgy, electroplating, food, pickling and other industries. It is an ideal equipment for building civilized factories to prevent running, emitting and leaking.

1. Acid-resistant type: suitable for conveying all kinds of strong acid or acid and solvent mixture.

2. Alkali-resistant type: suitable for conveying alkaline clear liquid or alkaline liquid mixed with solvent.

3. Impurity-resistant type: suitable for acidic or alkaline liquid containing a small amount of solid material in the conveying medium. If the solid content is large, the CUHB-ZK series corrosion-resistant slurry pump can be used, or the selection can be negotiated with the factory.

4. Explosion-proof type: suitable for conveying flammable and explosive liquids and equipped with explosion-proof motors.

5. Type selection condition table: When it is difficult to select a model, please fill in the type selection condition table and fax or mail it to our company to assist in type selection.

Model Description

Example: 50FSB(L)-25

50 -- Pump inlet diameter is 50mm

FSB-Overcurrent components are made of fluoroplastic

L-straight-link structure (no L is bracket structure)

25 -- lift is 25m

-

Flow: 3.6~100 m3/h

Head: 15~55m

Speed: 2900r/min

Power: 1.5 ~ 18.5KW

Inlet diameter: 25~100mm

Applicable temperature:-20 ℃ ~ 120 ℃

Inlet pressure: ≤ 0.3 MPa (above 0.3 MPa, please declare)

Sealing form: mechanical seal

Water pump material: fluorine plastic

-

-

Pump Removal

1. The pump and the motor are connected with claw coupling. When disassembling, loosen the 4 connecting bolts between the bracket and the base. Disconnect the pump from the motor.

2. Loosen the connecting bolt of the back cover of the pump body, and tap the pump body with a wooden handle to disengage.

3. Loosen the hanging bolt connecting the impeller shaft and the pump shaft Morse taper in the coupling.

4. Loosen the mechanical seal, do not fix the screw, use a wooden hammer to tap the central hoisting bolt of the coupling, and pull out the impeller, rear cover and seal moving ring after the impeller shaft and pump shaft are loosened. Loosen the screw of the gland on the rear cover and take it out.

5. Loosen the left and right gland screws of the pump shaft, take out the pump shaft and bearing, and clean the oil chamber of the bracket.

Assembly

Install the fastening bolts on the seal moving ring, static ring, back cover, gland, impeller, pump body, etc. in the reverse order of disassembly.

Installation and Precautions

1. The pump and motor should be inspected before installation. All parts should be intact and there is no debris in the pump.

2. Place the pump in a horizontal position, connect the inlet and outlet pipes and connect the power supply, then turn the coupling by hand to check whether there is any rubbing phenomenon, and the installation is finished when the rotation is easy and uniform.

3. The steel degree of plastic alloy centrifugal pump is worse than that of metal, so the weight of the pipeline cannot be directly pressed on the pump body. The burst and outlet pipelines should be supported by additional supports. The pump with high lift should also be equipped with a check valve at the outlet to prevent water hammer damage caused by sudden shutdown.

4. All joints must be sealed to prevent air leakage and liquid from affecting the working performance of the pump.

5. In the process of operation, if you find a pursed or abnormal sound, you should immediately stop and check the cause, and then you can work after troubleshooting.

Start and stop

1. Pour enough liquid into the water pump (lead liquid).

2. Check whether the oil level of the oil chamber of the bracket is within the specified range.

3. Check the running direction of the motor and check the rotation mark of the pump.

4. Close the outlet valve and pressure gauge cock.

5. Start the motor, open the pressure gauge cock, slowly open the outlet valve, when the pressure.

6. When it is important to stop, first close the outlet valve and then cut off the power supply. When the pressure gauge pointer points to the required position. Stop the adjustment of the size of the outlet valve.

-

Causes and Solutions of 1. Fluoroplastic Centrifugal Pump Not Liquid in Operation

(1) Insufficient liquid in the pump chamber (the gas in the pump is not exhausted). Solution: re add liquid, pump cavity filled with liquid.

(2) Whether the pump operation and steering are correct when the equipment is started. Solution: check the supporting motor running direction.

(3) The speed of the pump is low after starting. Solution: stop to check the motor speed, replace the corresponding speed motor power.

(4) The filter screen at the inlet end is blocked. Solution: check the filter, remove debris, etc.

(5) The suction height is greater than the actual suction height of the pump, and the suction tank is vacuum. Solution: Reduce the suction height and check the pressure of the suction tank.

Causes and solutions of interruption after discharge of 2. fluoroplastic centrifugal pump

(1) Inlet pipeline leaks. Solution: check whether the inlet pipe connection and packing seal leakage.

(2) When filling the pump, the gas at the inlet end is not completely discharged. Solution: Require a refillable pump.

(3) The inlet end is blocked by foreign matter. Solution: stop the pump to deal with foreign matter.

(4) Intake a large amount of gas at the inlet. Solution: Check whether the suction port is vortex and whether the submerged depth is too shallow.

Vibration Causes and Solutions of 3. Fluoroplastic Centrifugal Pump

(1) the pump axis and the motor axis error is large. Solution: Readjust the position of the two axes.

(2) The suction height is too large, resulting in cavitation. Solution: Reduce the installation height.

(3) there is a phenomenon of mechanical friction. Solution: check where wear, maintenance.

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!