Recommend Products

Contact Us

| Email: | sales@sanchangpump.com |

| Hotline: | +86 133 0748 1676 |

| +86 193 1300 1794 | |

| Mobile: | +86 133 0748 1676 |

| Wechat: | +86 193 1300 1794 |

| Address: | No.517,Xiangfu Road |

| Yuhua District, | |

| Changsha City | |

| Hunan Province, P.R.C |

DFP Seawater Injection Pump Boosting Output from Mature Subsea Fields

Classification:

Seawater desalination pump

Seawater desalination pump

Key words:

water pump

Lift range: H = 50-1800m

Conveying temperature:-20-150 ℃ (please declare above 80 ℃)

Inlet pressure: less than 0.6MPa

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

Hotline:

- Product Description

- Performance Parameter

- Installation Drawings

- Installation And Use

- Faults And Solutions

-

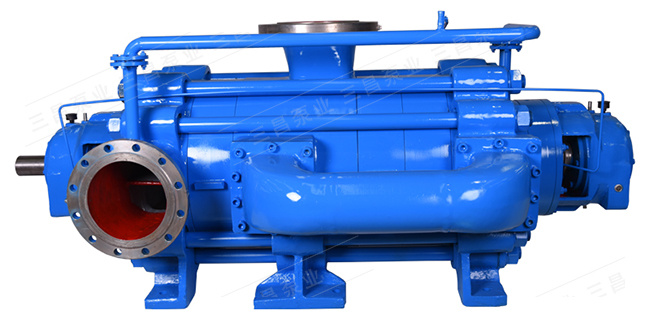

- Commodity name: DFP Seawater Injection Pump Boosting Output from Mature Subsea Fields

Flow range: Q = 3.75-1100 m3/h<br>Lift range: H = 50-1800m<br>Conveying temperature:-20-150 ℃ (please declare above 80 ℃)<br>Inlet pressure: less than 0.6MPa<br>Sealing form: packing seal, mechanical seal<br>Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc</br></br></br></br></br>

Seawater Injection Pump

China is a country with poor water resources, and there is a serious shortage of water resources in coastal areas. Seawater desalination is one of the effective ways to solve the serious shortage of fresh water in coastal areas of China, and with the progress of technology, reverse osmosis desalination technology has become the leading technology of seawater desalination in recent years because of its small equipment investment, low energy consumption, short construction period and many other advantages.

Reverse osmosis seawater desalination technology (hereinafter referred to as: SWRO) is the use of the permeable characteristics of the semi permeable membrane, with a pump to pressurize the sea water, so that water molecules overcome the resistance and through the semi permeable membrane, so as to achieve the purpose of separation of fresh water from seawater. Seawater desalination high-pressure pump is the core power equipment of seawater desalination, which provides the energy to overcome osmotic pressure in membrane desalination, and the efficiency of the pump directly determines the energy consumption index of reverse osmosis seawater desalination system. Choosing the right high-pressure pump has an important impact on the economy of seawater desalination system.

Selection of seawater desalination pump and problems needing attention

To select the right pump, you need to know basic data such as water volume, pump pressure range, and pump performance curves. In the reverse osmosis seawater desalination system, the investment cost accounts for about 25% of the desalinated water cost per ton, and the electricity cost accounts for more than 52%. The two items together account for more than 77% of the water production cost. In the cost of electricity, the energy consumption of the high-pressure pump is the main factor, therefore, the energy consumption of the high-pressure pump is the main factor affecting the cost of product water, according to different desalination scale to choose high-efficiency, appropriate high-pressure pump is the current reverse osmosis seawater desalination industry urgently need to solve the problem. So what are the problems that need to be paid attention to in the selection of high-pressure pumps for seawater desalination equipment?

1. The form and scope of application of common seawater desalination high-pressure pumps

There are two main types of high-pressure pumps commonly used in membrane desalination systems: multi-stage centrifugal pumps in power pumps and plunger pumps in positive displacement pumps. In general, multi-stage centrifugal pumps are mainly suitable for large and medium-sized seawater desalination devices, and plunger pumps are mainly suitable for small and medium-sized seawater desalination devices. There is no specific data on the capacity demarcation of large, medium and small seawater desalination, which is due to the high efficiency of plunger pumps and changes in investment trends brought about by the parallel operation of some plunger pumps, especially for B00 or BOT projects, where the energy consumption for full life cycle operation is the first.

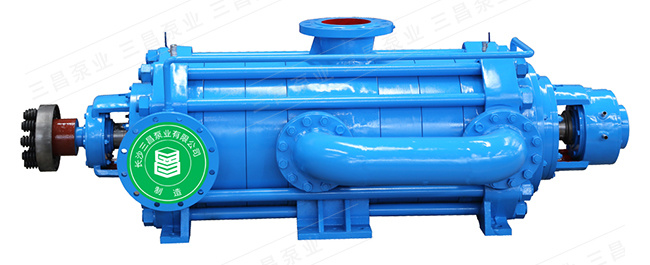

Commonly used multi-stage centrifugal pumps are divided into horizontal and multi-stage series types from the structural form.

Horizontal open structure features:

The upper and lower pump housings are connected, and the inlet and outlet pipes, part of the volute and the runner are cast on the lower pump housing. The impeller is hot-mounted on the shaft and symmetrically arranged, which reduces the axial thrust to the greatest extent. The thrust bearing bears less axial thrust and lower vibration. Maintenance is relatively convenient. During maintenance, the upper shell of the pump can be directly removed without disassembling the pipeline of the pump.

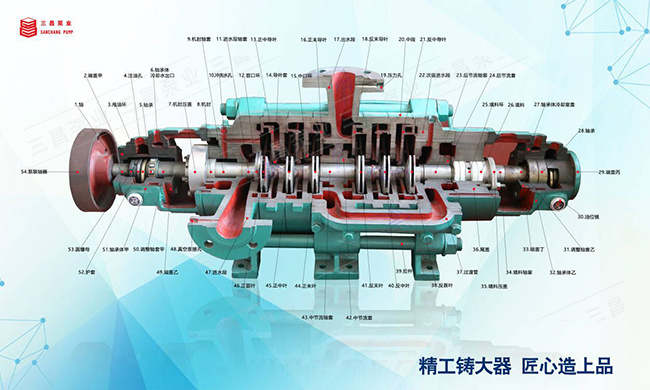

Multi-stage tandem pump structure features:

Each stage is composed of an impeller located in the diffuser housing. The diffuser is connected with a bolt and a connecting rod. All stages are fixed together in series by a fixed rod; the impeller is assembled in one direction and fixed on the pump shaft with a key, similar to the string sugar gourd; it has higher efficiency at the best efficiency point, but the efficiency is lower when it deviates, the vibration increases, and the disassembly and assembly are difficult.

Compared to the two in the structure should be the level of open type accounted for a larger advantage, but because the level of open type equipment is expensive, so both have a wide range of applications. The piston pump is a kind of positive displacement pump, which is widely used in the occasions where high lift and small flow are required. Such as cleaning industry oil industry.

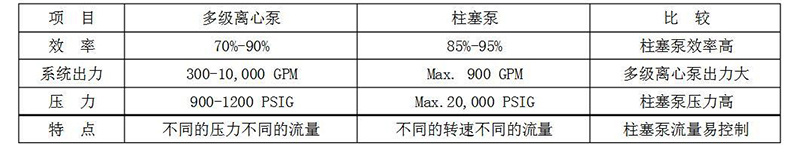

Multi-stage centrifugal pump and plunger pump compared, due to the different working principle, in practical application, there is a big difference, the following table for the centrifugal pump and plunger pump simple comparison:

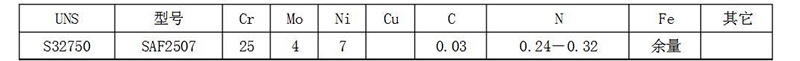

2, the selection of seawater desalination high-pressure pump needs to pay attention to the problem

The correct selection of high-pressure pump is the key to the safe and economical operation of the system. For a high-pressure pump of a membrane desalination system, whether it is a plunger pump or a centrifugal pump, the first thing to determine is the material of the flow part, that is, to solve the corrosion problem of the pump in seawater. At present, there are many optional materials. Based on economic considerations, 2507(UNS:S32750) duplex stainless steel is generally selected. The main rated chemical composition is as follows.

As can be seen, N is added to 2507 to ensure the formation of dual phases (austenite-ferrite), recommend the main reason for using 2507 is to avoid chloride ion corrosion under stress.

Because the large-scale seawater desalination device can only use multi-stage centrifugal pump. For multi-stage centrifugal pumps, the following issues should generally be considered:

Choose a high efficiency pump, because the efficiency directly affects the economy of the system;

The high efficiency of the water pump covers a wide range of choices, because the flux of SWRO will decay, and the working point of the water pump will drift;

③ The flow rate changes less when the head changes, because there are many factors affecting the osmotic pressure of SWRO, and the pump should work at different working points, but the capacity and recovery rate of SWR0 do not change much;

Choose a pump that is easy to maintain.

Application of Seawater Desalination Pump in Liuheng Seawater Desalination Project

The Liuheng Island 100000-ton seawater desalination project is a key project in Zhejiang Province, and a platform project for the national "Eleventh Five-Year" science and technology support plan "Development and Demonstration Project of Key Technologies for Domestic Production of 100000-ton Reverse Osmosis Membrane Desalination. After the project is completed, it will become the largest seawater desalination project in the country. The high-pressure seawater desalination pump provides sufficient water inlet pressure for the reverse osmosis seawater desalination membrane group of the project, and at the same time provides the pressure and flow required for the normal operation of the reverse osmosis membrane group in combination with energy recovery.

Because the water temperature has a great influence on the reverse osmosis membrane flux, in order to save energy and reduce operating costs, the high-pressure pump can use liquid force coupling or frequency conversion to adjust the load control. After comparing the two speed control schemes of liquid force coupling or frequency conversion control, the frequency conversion control scheme is used to control the speed.

The materials of reverse osmosis high-pressure pumps, pipes and accessories are considered to be corrosion resistant. The sealing method considers corrosion-resistant mechanical seals.

② The inlet and outlet of the reverse osmosis high-pressure pump are equipped with pressure switches. When the inlet pressure is low, the pump will be alarmed and stopped, and when the outlet pressure is high, the pump will be alarmed and stopped.

Through the comparison of centrifugal pump and plunger pump, the high-pressure pump of this project adopts multi-stage centrifugal pump (2205SS duplex stainless steel material). The single pump has a flow rate of 10000 tons/day, a lift of 600m, a motor power of 1040kW and a voltage of 690kV.

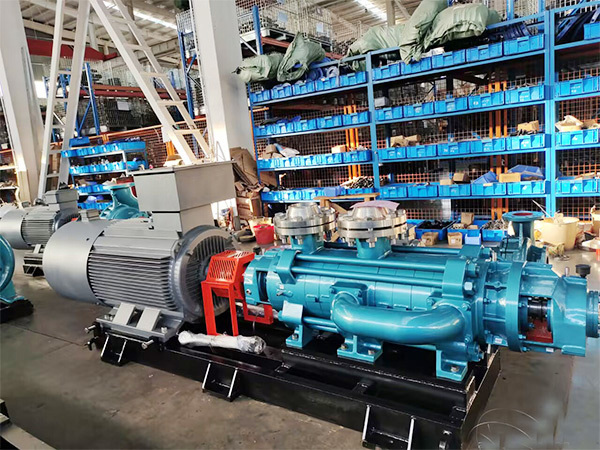

Development Trend of Seawater Desalination Pump

At present, there are fewer domestic manufacturers of high-pressure centrifugal pumps, and even fewer of them can be used in SWRO systems. High-pressure seawater desalination pumps require higher efficiency than ordinary multistage centrifugal pumps. According to the needs of the market, Sanchang pump industry accelerates the development of high-pressure multi-stage centrifugal pump technology. The self-developed high-efficiency self-balancing multi-stage pump is a high-speed high-pressure pump product suitable for SWRO system. The self-balancing multi-stage pump is based on the structure of a segmented multi-stage centrifugal pump, adopts a non-balancing device and an efficient hydraulic model, and runs continuously for 8000 hours without failure. Because there is no balance device, that is, there is no balance disc friction loss and no balance return loss, the pump efficiency is 3%-14% higher than that of multi-stage pumps of the same category, and various faults such as wear or rotor seizure of the pump balance disc and balance disc seat caused by the failure of the balance device are completely solved, thus greatly prolonging the service life of the pump. The unique structural strength design has the advantages of strong mechanical sealing, corrosion resistance, low noise, small volume, easy maintenance, etc. The combined structure design of water lubricated bearing and rolling bearing is adopted to replace the structure of double rolling bearing of traditional multistage pump. The front sealing ring of the first impeller is also used as the innovative support structure of sliding bearing. The duplex stainless steel overcurrent components are optimized. The single machine meets the requirements of 5000t/d reverse osmosis seawater desalination, the efficiency is as high as 80%, which is significantly higher than similar products at home and abroad.

Advanced Technology of Sanchang High Efficiency Self-balancing Multistage Centrifugal Pump

The design of this series of pumps is based on the practical safety, economy, trouble-free operation and low maintenance costs of the whole process of pump operation. The main design features of the pump are briefly described as follows

● Advanced modular design, a large number of local components that have passed the test of long-term operation, and the parts have a high degree of interchangeability.

● High-strength, high-quality materials and a variety of choices of inlet and outlet flange and nozzle design improve the high allowable pipe load of the pump. The high-strength, high-quality pump casing material has a tight structure, and its service life can reach 5 times that of ordinary castings. The impeller and guide vane at the over-flow part are precision cast, and the efficiency is improved by more than 2% compared with ordinary castings.

With the development of domestic seawater desalination high-pressure pump technology, Sanchang Pump will continue to increase investment in the development and production of seawater desalination high-pressure pumps. In the future, the self-balancing multi-stage high-pressure pump produced by Sanchang Pump will be widely used in seawater desalination projects.

-

Flow range: Q = 3.75-1100 m3/h

Lift range: H = 50-1800m

Conveying temperature:-20-150 ℃ (please declare above 80 ℃)

Inlet pressure: less than 0.6MPa

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

-

Previous Page

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!