Recommend Products

Contact Us

| Email: | sales@sanchangpump.com |

| Hotline: | +86 133 0748 1676 |

| +86 193 1300 1794 | |

| Mobile: | +86 133 0748 1676 |

| Wechat: | +86 193 1300 1794 |

| Address: | No.517,Xiangfu Road |

| Yuhua District, | |

| Changsha City | |

| Hunan Province, P.R.C |

Diesel Engine Double Suction Centrifugal Pump

Classification:

BB1 Double Suction Split Case Pump

S-type horizontal single-stage double-suction pump

Urban water supply

Key words:

water pump

Lift range: 8-280m

Conveying temperature: ≤ 80 ℃

Inlet pressure: less than 1.6MPa

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

Hotline:

- Product Description

- Performance Parameter

- Installation Drawings

- Installation And Use

- Faults And Solutions

-

- Commodity name: Diesel Engine Double Suction Centrifugal Pump

Flow range: 50~6000 m3/h<br>Lift range: 8-280m<br>Conveying temperature: ≤ 80 ℃<br>Inlet pressure: less than 1.6MPa<br>Sealing form: packing seal, mechanical seal<br>Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc</br></br></br></br></br>

S-type Diesel Engine Double-suction Split Case Centrifugal Pump is a new structure water pump product successfully developed by our company's technicians on the basis of the same type of products. The structure is divided into horizontal, single-stage and horizontal medium-open type. It is suitable for conveying other liquids with physical and chemical properties similar to clear water. The medium temperature should not be higher than 80 degrees Celsius. This type of water pump is widely used in various applications such as process water supply systems, fire protection systems, fire protection systems, urban flood control and drainage.

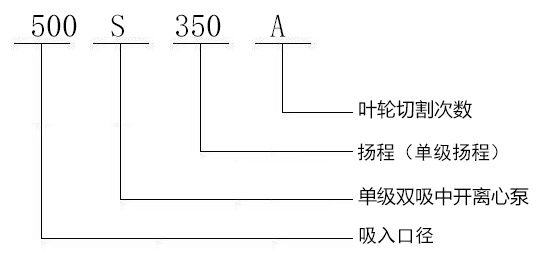

Model Description

Example: 500 S 35A;

500-pump inlet diameter 500mm;

S-single-stage, double-suction, open centrifugal clean water pump;

35-design point lift 35m;

A- Impeller first cut.

Transmission mode

This type of water pump transmission mode can be divided into direct transmission and variable speed transmission. Please specify the motor model, power and speed before ordering, so that we can determine the specifications of the coupling or pulley.

Rotation direction of water pump

From the pump side, the pump rotation direction is counterclockwise.

Material Description

Materials are copper, iron, ductile iron, 316,304 stainless steel, 416; two-way steel, Hastelloy, Monnai alloy, titanium alloy and alloy 20 and other materials.

Conditions of use

1) Water pump ambient temperature ≤ 50 ℃, water pump medium temperature ≤ 80 ℃.

2) PH value of water pump medium cast iron material is 6-9.

3) The medium weight of the pump shall not exceed 1240kg/m3.

4) The bottom valve shall be installed and the water shall be filled. The suction height of the water pump shall be ≤ 6 m, and the length of the suction pipe shall be ≤ 10 m.

Performance characteristics

The inlet and outlet are all below the axis of the water pump and form a vertical and horizontal direction with the axis of the water pump. When the water pump is overhauled, there is no need to disassemble the inlet and outlet water pipes and the motor of the water pump. The rotation direction of the water pump is counterclockwise when viewed from one end of the water pump (the rotation direction of the water pump can also be changed according to user requirements).

The main parts are pump body, pump cover, impeller, shaft, double suction seal ring, shaft sleeve, etc., in addition to the pump shaft material for carbon steel, other parts of the material made of cast iron, cast steel, stainless steel manufacturing.

The pump body and the pump cover form the pump impeller working room. The inlet and outlet flanges of the pump are provided with screw holes for installing vacuum gauge and pressure gauge, and the lower part of the inlet and outlet flanges of the pump is provided with threaded holes for discharging water.

After static balance detection of the impeller, the shaft sleeve nut is fixed on the pump shaft, the axial position can be adjusted by the shaft sleeve nut, and the axial force of the impeller is balanced by the symmetrical arrangement of the blades and the water on both sides.

The water pump bearing is a radial bearing, which is installed in the bearing body. Both ends of the water pump bearing are installed to fix the bearing operation and are lubricated with butter.

The main function of the double suction sealing ring is to reduce the water leakage of the pressure chamber back to the suction chamber.

The water pump is connected to the motor through the coupling, and the motor drives the water pump to rotate, or it can be driven by an internal combustion engine as needed.

The shaft seal is a soft packing seal (mechanical seal can also be installed according to user needs). In order to prevent air from entering the pump body and cooling and lubricating the sealing cavity, a packing ring is installed between the packing. When the water pump is working, a small amount of high-pressure water flows into the packing cavity through the trapezoidal groove on the open surface of the pump cover to play the role of water seal.

-

Flow range: 50~6000 m3/h

Lift range: 8-280m

Conveying temperature: ≤ 80 ℃

Inlet pressure: less than 1.6MPa

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

Previous Page

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!