Recommend Products

Contact Us

| Email: | sales@sanchangpump.com |

| Hotline: | +86 133 0748 1676 |

| +86 193 1300 1794 | |

| Mobile: | +86 133 0748 1676 |

| Wechat: | +86 193 1300 1794 |

| Address: | No.517,Xiangfu Road |

| Yuhua District, | |

| Changsha City | |

| Hunan Province, P.R.C |

SH type single stage double suction open pump

Classification:

BB1 Double Suction Split Case Pump

SH type single stage double suction open pump

Water conservancy industry

Petrochemical industry

Electric power industry

Urban water supply

Key words:

water pump

Head range: H = 10~280m

Conveying temperature:-20-80 ℃

Inlet pressure: less than 0.6MPa

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

Hotline:

- Product Description

- Performance Parameter

- Installation Drawings

- Installation And Use

- Faults And Solutions

-

- Commodity name: SH type single stage double suction open pump

Flow range: Q = 160~18000 m3/h<br>Head range: H = 10~280m<br>Conveying temperature:-20-80 ℃<br>Inlet pressure: less than 0.6MPa<br>Sealing form: packing seal, mechanical seal<br>Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc</br></br></br></br></br>

S,SH type horizontal single-stage double-suction horizontal open agricultural centrifugal pump is a new high-efficiency and energy-saving product, which has a wider application range than SA and SH. The use of standard design, its serialization, standardization, high degree of generalization, the pump advanced performance, stable operation, safe and reliable, in the design of the new structure, new materials, can be applied to a variety of media transport.

For the delivery of water or physical and chemical properties similar to water liquid.

Widely used in urban water supply and drainage, power stations, industrial process system of water intake, pressure, farmland irrigation and drainage and various water conservancy projects, petrochemical projects.

Structure Description

Both the suction inlet and the discharge outlet are below the axis of the pump and are perpendicular to the axis in a horizontal direction. There is no need to dismantle the inlet and outlet water pipes and the motor during maintenance. From the transmission direction, the pump is clockwise rotation (according to user needs can also be changed to counterclockwise rotation).

The main parts are: pump body, pump cover, impeller, shaft, double suction seal ring, shaft sleeve, etc. In addition to the shaft material is high-quality carbon steel, the rest of the main parts are made of cast iron, cast steel, stainless steel.

The pump body and the pump cover constitute the working chamber of the impeller, and the inlet and outlet flanges are equipped with pipe screw holes for installing vacuum gauges and pressure gauges. The lower part of the water inlet and outlet flange is equipped with a threaded pipe hole for water discharge.

After static balance test, the impeller is fixed on the shaft with the shaft sleeve and the shaft sleeve nut on both sides, and its axial position can be adjusted by the shaft sleeve nut. The axial force of the impeller is balanced by the symmetrical arrangement of the blades and the water on both sides.

The bearings are radial ball bearings. The bearing is installed in the bearing body, installed at both ends of the pump body, and lubricated with butter.

The sealing ring is used to reduce the water leakage of the water pump pressure chamber back to the suction chamber.

Direct drive by the motor through the elastic coupling, if necessary, can also be used for internal combustion engine transmission.

The shaft seal is a soft packing seal (can also be installed as required). In order to prevent air from entering the pump and cooling the lubrication seal cavity, a packing ring is installed between the packing. When the water pump is working, a small amount of high-pressure water flows into the packing cavity through the trapezoidal groove on the open surface of the pump cover to play the role of water seal.

Material Description

The material can be copper, cast iron, ductile iron, 316 stainless steel, 416 steel; 7 stainless steel, two-way steel, Hastelloy, Monnai alloy, titanium alloy and 20 alloy and other materials.

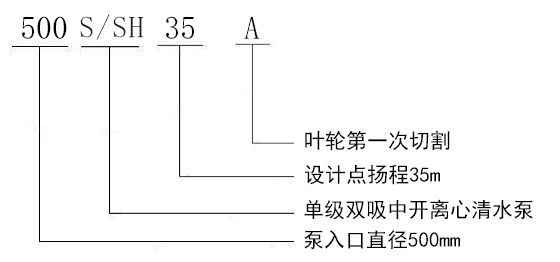

Model Description

Example: 500 S/SH 35A

500-Pump inlet diameter 500mm

S/SH-Single stage, double suction, open centrifugal fresh water pump

35-Design point lift 35m

A- Impeller first cut

-

流量范围:Q=160~18000m3/h

扬程范围:H=10~280m

输送温度:-20-80℃

进口压力:小于0.6MPa

密封形式:填料密封、机械密封

水泵材质:HT200、HT250、QT600、ZG、304、316、316L、317L、904L、CD4-MCu等

-

-

装配与拆卸

1 、装配转子部件:依次将叶轮、轴套、轴套螺母、填料套、填料环、填料压盖,挡水圈、轴承部件装在泵轴上,并套上双吸密封环,然后装上联轴器。

2、将转子部件装在泵体上,调整叶轮的轴向位暈到两侧双吸密封环的中间加以固定,将轴承体压盖同固定螺钉紧固。

3、装上填料,放好中开面纸垫,盖上泵盖打紧螺尾柱销后,拧紧泵盖螺母,最后装上墳料压盖。但不要将填料压得太紧,填料过紧会使轴套发热,耗费功率较大,也不要压得太松,过松会使 液体渗漏大,水泵效率降低。

装配完成后,用手转动泵轴,没有擦碰现象,转动比较轻滑均勻即可,拆卸可按上述装配顺序相反地进行。

安装检查:

1 、检査水泵和电动机应无损坏。

2、水泵的安装高度,加上吸入管路的水力损失,及其速度能,不得大于样本规定的允许吸上真空高度值。基础尺寸应符合泵机组的安装尺寸。

3、安装顺序:

① 将水泵放在埋有地脚螺栓的混凝土基础上,用调整其间的楔型垫块的方法校正水平,并适当拧紧地脚螺栓,以防走动。

② 在基础与泵底脚之后灌注混凝土 。

③ 待混凝土干固后,拧紧地脚螺栓,并重新检査水泵的水平度。

④ 校正电动机轴与水泵轴的同心度。使两轴成一直线,在两轴器外圆上的同轴度允差为0.1mm,端面间隙沿圆周的不均匀度允差0.3mm(在联接进出水管路及试运行后再分别校核一遍,仍应符台上述要求)。

⑤ 在检査电动机转向与水泵转向一致后,装上联轴器及联接柱销。

4、进出水管路应另设支架支撑,不得籍泵本体支承。

5、水泵与管路之间的结台面,应保证良好的气密性,尤其是进水管路,必须保证严格的不漏气,并且在装置上应无窝存空气的可能。

6、如水泵安装在进水水位以上吋,为了灌泵起动,一般可装底阀。也可采用真空引水的方法。

7、水泵与出水管路之后,一般需装闸阀和止回阀(扬程小于20米的可不用),止回阀装在闸阀后面。以上所述的安装方法是指不配带公共底座的水泵机组。

安装配带公共底座的泵,用调整底座与混凝土基础之间的楔形垫铁来校正机组的水平。然后在其间灌注混凝土。其安装原则与要求,和不配带公共底座的机组相同。

泵启动、停止与运行

1、起动与停止:

起动前,转动泵的转子,应该轻滑均匀。

② 关闭出水闸阀,向泵内注不(如无底阀则用真空泵抽空引水)要保证泵内充满水.无空气窝存。

③ 如果泵上装有真空表或压力表.要关闭其与泵相连接的旋基再起动电动机.待转速正常后再打开;然后逐渐打开出水闸阀,如流置过大,可以适当地关小闸阀进行调节;反之流量过小时.将闸阀开大。

④ 均匀地拧紧填料压盖上的压紧螺母,使液体成滴状漏出.同时注意填料腔处的溫升。

⑤ 当停止水泵运转时.要先关闭真空表及压力表的旋塞和出水管路上的闸阀.然后关闭电动机的电源.如

所处环境的温度较低时,则应将泵体下部的四方螺塞打开.去掉?水.以免冻裂。⑥长期停止使用时.应拆开水泵将另件上的水擦干.在加工表面涂上防锈油保管好。

2、运转:

① 水泵轴承最高溫度不应超过75°C。

② 润滑轴承用的钙基黄油的数量以占轴承体空间的1/3~1/2为宜。

③ 填料磨损吋可适当压紧填料压盖.若磨损过多应加以更換。

④ 定期柁査眹轴器部件.注意电机轴承温升。

⑤ 运转过程中.如发现矂声或其他不正常的声音时,应立即停车.检査其原因.加以消除。

⑥ 不得任意提高水泵的转速.但可以降低转速使用.如本型泵额定转速为n流量为Q,扬程为H.轴功率为N,降低转速为n1.降速后流量.扬程.轴功率分别为Q1 、H1和N1.其相互关系.可用下列公式迸行换算:

Q1=(n1/n)Q H1=(n1/n)²H N1=(n1/n)³N

Next Page

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!