Recommend Products

Contact Us

| Email: | sales@sanchangpump.com |

| Hotline: | +86 133 0748 1676 |

| +86 193 1300 1794 | |

| Mobile: | +86 133 0748 1676 |

| Wechat: | +86 193 1300 1794 |

| Address: | No.517,Xiangfu Road |

| Yuhua District, | |

| Changsha City | |

| Hunan Province, P.R.C |

S Double Suction Split Case Pump Horizontal Single-stage Centrifugal pump

Classification:

BB1 Double Suction Split Case Pump

S-type horizontal single-stage double-suction pump

Water conservancy industry

Petrochemical industry

Electric power industry

Urban water supply

Key words:

water pump

Head range: H = 10~280m

Conveying temperature:-20-80 ℃

Inlet pressure: less than 0.6MPa

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

Hotline:

- Product Description

- Performance Parameter

- Installation Drawings

- Installation And Use

- Faults And Solutions

-

- Commodity name: S Double Suction Split Case Pump Horizontal Single-stage Centrifugal pump

Flow range: Q = 160~18000 m3/h<br>Head range: H = 10~280m<br>Conveying temperature:-20-80 ℃<br>Inlet pressure: less than 0.6MPa<br>Sealing form: packing seal, mechanical seal<br>Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc</br></br></br></br></br>

S,SH type horizontal single-stage double-suction horizontal open agricultural centrifugal pump is a new high-efficiency and energy-saving product, which has a wider application range than SA and SH. The use of standard design, its serialization, standardization, high degree of generalization, the pump advanced performance, stable operation, safe and reliable, in the design of the new structure, new materials, can be applied to a variety of media transport.

For the delivery of water or physical and chemical properties similar to water liquid.

Widely used in urban water supply and drainage, power stations, industrial process system of water intake, pressure, farmland irrigation and drainage and various water conservancy projects, petrochemical projects.

Application

* Fire Protection

* Water Transfer

* Municipal Water Supply

* Irrigation

* Industry

* Process Water

* Raw Water Supply

* Dewatering (Clean Water)

* Flood MitigationMaterial Description

The material can be copper, cast iron, ductile iron, 316 stainless steel, 416 steel; 7 stainless steel, two-way steel, Hastelloy, Monnai alloy, titanium alloy and 20 alloy and other materials.

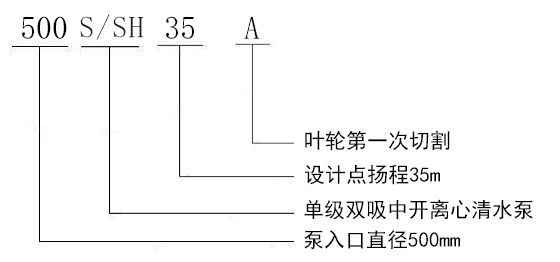

Model Description

Example: 500 S/SH 35A

500-Pump inlet diameter 500mm

S/SH-Single stage, double suction, open centrifugal fresh water pump

35-Design point lift 35m

A- Impeller first cut

-

Flow range: Q = 160~18000 m3/h

Head range: H = 10~280m

Conveying temperature:-20-80 ℃

Inlet pressure: less than 0.6MPa

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

-

-

Installation of S-type open pump

1, check the S-type open pump and motor should be no damage.

2. The installation height of the water pump, plus the hydraulic loss of the suction pipeline and its speed energy, shall not be greater than the allowable suction vacuum height value specified in the sample. The size of the foundation shall conform to the installation size of the pump unit

3. Installation sequence:

① Place the water pump on the concrete foundation buried with anchor bolts, adjust the level by adjusting the wedge-shaped cushion block between them, and tighten the anchor bolts appropriately to prevent walking.

② Concrete shall be poured between foundation and pump foundation.

③ After the concrete is dry and solid, tighten the anchor bolts and recheck the levelness of the S-type open pump.

④ Correct the concentricity of the motor shaft and the pump shaft. Make the two axes in a straight line, the coaxiality tolerance on the two axes is 0.1mm, and the unevenness tolerance of the end face clearance along the circumference is 0.3mm (in

After connecting the water inlet and outlet pipes and correcting them separately after trial operation, the above requirements shall still be met).

⑤ After checking that the steering direction of the motor is consistent with that of the water pump, install the coupling and the connecting pin.

4. The inlet and outlet pipes shall be supported by another bracket, and shall not be supported by the pump body.

5. The joint surface between the water pump and the pipeline should ensure good air tightness, especially the water inlet pipeline, which should strictly ensure that there is no air leakage, and there should be no possibility of air storage on the device.

6. If the S-type intermediate pump is installed above the inlet water level, the bottom valve can be installed in order to start the pump. The method of vacuum water diversion can also be used.

7. Gate valves and check valves are generally required between the water pump and the outlet pipeline (those with a lift of less than 20m are not required), and the check valves are installed behind the gate valves.

The installation method mentioned above refers to the water pump unit without a common base.

Install the pump with common base, adjust the level of the unit by adjusting the wedge between the base and the concrete foundation. Concrete is then poured in. The installation principle and requirements, and not with a common base unit of the same.

Starting, stopping and running

1. Start and stop:

Before starting, rotate the pump rotor, should be smooth and even.

② Close the outlet gate valve and inject water into the pump (if there is no bottom valve, use vacuum pump to evacuate and divert water). Ensure that the pump is full of water and there is no air reservoir.

③ If the pump is equipped with a vacuum gauge or pressure gauge, close the cock connected with the pump and start the motor again, and then open it after the speed is normal; then gradually open the outlet gate valve, such as the flow is too large, you can properly close the gate valve Adjust; otherwise, open the gate valve when the flow is too small.

④ Tighten the compression nut on the packing gland evenly to make the liquid leak out in drops, and pay attention to the temperature rise at the packing cavity.

⑤ When stopping the operation of the pump, close the cock of the vacuum gauge and the pressure gauge and the gate valve on the outlet pipe, and then turn off the power supply of the motor. If the ambient temperature turns low, open the square screw plug at the lower end of the pump body to drain the residual water to prevent the pump body from freezing and cracking.

⑥ When long-term use is stopped, the water pump should be disassembled to dry the water on the parts, and the processed surface should be coated with anti-rust oil for storage.

2. Operation:

① The maximum temperature of the water pump bearing shall not exceed 75 ℃.

② The amount of calcium-based butter used to lubricate the bearing should account for 1/3~1/2 of the bearing body space.

③ When the packing is worn, the packing gland can be properly pressed. If there is too much hemp damage, it should be replaced.

Check the coupling parts regularly and pay attention to the temperature rise of the motor bearing.

⑤ During operation, if noise or other abnormal sounds are found, stop immediately, check the cause and eliminate it.

⑥ The rotating speed of the water pump shall not be increased arbitrarily, but the rotating speed can be reduced. For example, the rated rotating speed of the pump is N, the flow rate is Q, the lift is H, the shaft power is N, the rotating speed is reduced to n1, and the flow rate, lift and shaft power after speed reduction are Q1, H1 and N1 respectively. The interrelationship can be converted by the following formula.

Q1 = (N1/N) Q h1 = (N1/n)2 h N1 = (N1/n)3 N

Assembly and disassembly

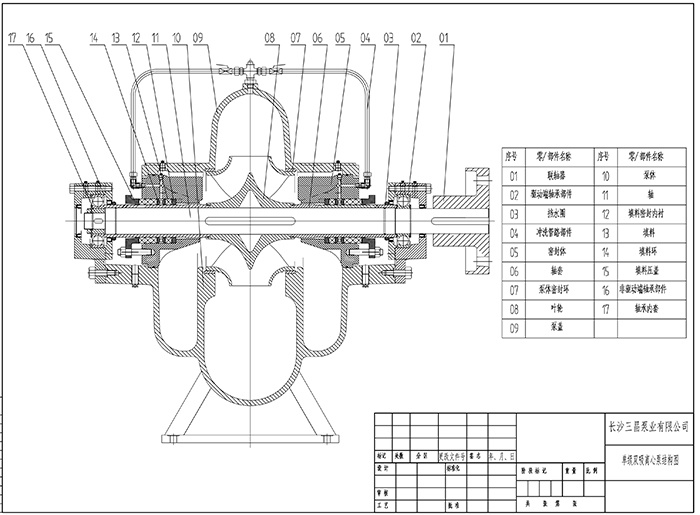

1. Assemble rotor components: assemble the impeller, shaft sleeve, shaft sleeve nut, packing sleeve, packing ring, packing gland, water retaining ring and bearing components on the pump shaft, and install the double-suction sealing ring, and then install the coupling.

2. Install the rotor parts on the pump body, adjust the axial position of the impeller to the middle of the double-suction sealing ring to be fixed, and fasten the gland of the bearing body with the fixing screw.

3. Install the packing, put the paper pad on the middle opening surface, cover the pump cover and tighten the screw tail pin, tighten the pump cover nut, and finally install the packing gland. However, do not press the packing too tightly. Too tight the real material will cause the shaft sleeve to heat up, consuming more power, and do not press too loosely. Too loose will cause large liquid leakage and reduce the efficiency of the pump.

After the assembly is completed, rotate the pump shaft by hand without rubbing. The rotation is relatively smooth and even. Disassembly can be carried out in the reverse order of the above assembly.

Next Page

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!