Recommend Products

Contact Us

| Email: | sales@sanchangpump.com |

| Hotline: | +86 133 0748 1676 |

| +86 193 1300 1794 | |

| Mobile: | +86 133 0748 1676 |

| Wechat: | +86 193 1300 1794 |

| Address: | No.517,Xiangfu Road |

| Yuhua District, | |

| Changsha City | |

| Hunan Province, P.R.C |

IY horizontal single-stage centrifugal oil pump

Classification:

Petrochemical industry

Single-stage End Suction Pump

IY horizontal single-stage centrifugal oil pump

BB2 Pump

IY horizontal single-stage centrifugal oil pump

Key words:

water pump

Head range: 8~125m

Conveying temperature:-20 ℃ ~ 150 ℃

Inlet pressure:< 0.8MPa

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

Hotline:

- Product Description

- Performance Parameter

- Installation Drawings

- Installation And Use

- Faults And Solutions

-

- Commodity name: IY horizontal single-stage centrifugal oil pump

Flow range: 6.3~400 m3/h<br>Head range: 8~125m<br>Conveying temperature:-20 ℃ ~ 150 ℃<br>Inlet pressure:< 0.8MPa<br>Sealing form: packing seal, mechanical seal<br>Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc</br></br></br></br></br>

Product Description

IY single-stage single-suction oil centrifugal pump, suitable for conveying non-corrosive and petroleum products without solid particles and viscosity less than 120 centistokes. It is also used to transport clean water or other liquids with physical and chemical properties similar to clean water, the temperature is not higher than 80 ℃, and the inlet pressure is not higher than 0.6MPa.

Overview

IY type single-stage single-suction centrifugal pump is the national joint design of energy-saving pump, it is BA type, B type and other single-stage water centrifugal pump update derived type. The advantages are: the whole series of hydraulic performance layout is reasonable, the user selection range is wide, the maintenance is convenient; the efficiency and suction reach the international average advanced level.

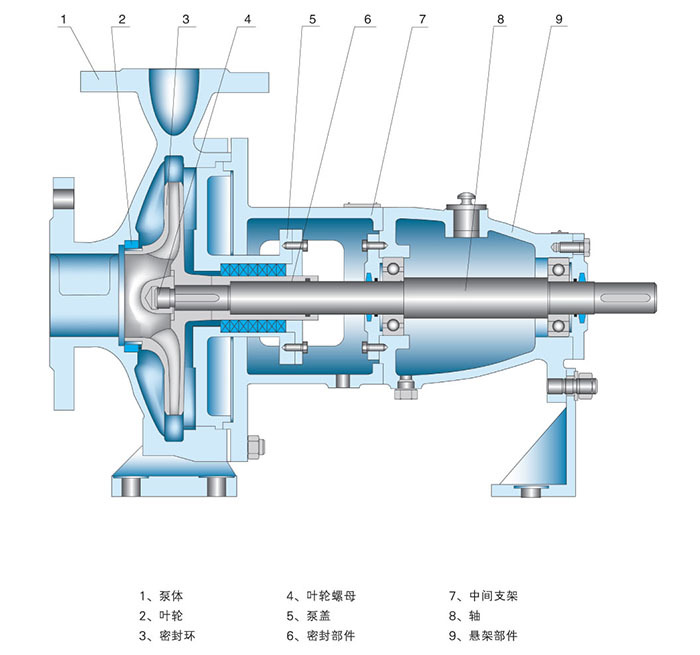

Structure Description

IY type single-stage centrifugal pump in line with national standards GB5662-85 equivalent adopted, international standards IYO2858 the provisions of the marking performance and size. It is mainly composed of pump body, pump cover, impeller, shaft, sealing ring, shaft sleeve and suspension bearing parts. The casing (I. e., the pump body and the pump cover) of the IY single-stage centrifugal pump constitutes the working chamber of the pump. Yangtze River pump impeller, shaft, and rolling bearings for the pump rotor. The suspension bearing part supports the rotor part of the pump, and the rolling bearing receives the radial and axial forces of the pump. In order to balance the axial force of the pump, most pumps have no sealing ring before and after the impeller, and a balance hole is provided on the back cover of the impeller. The axial seal of the water centrifugal pump is a soft packing seal, a mechanical seal and a rubber oil seal. The rotation mode of the water centrifugal pump is connected with the motor through the elastic coupling. From the driving end, the pump rotates clockwise.

Use

IY single-stage single-suction centrifugal oil pump is suitable for all kinds of light oil transportation and for the transportation of water or other liquids with physical and chemical properties similar to water, and the temperature is not high 80 ℃.

Product Features

1. IY single-stage single-suction centrifugal oil pump is designed according to the performance and size specified in international standard IYO2858. It is mainly composed of pump body, pump cover, impeller, shaft, sealing ring, shaft sleeve and suspension bearing.

2. The pump body and pump cover part of the IY single-stage single-suction centrifugal oil pump are split from the back of the impeller, which is commonly referred to as the rear door opening structure. Its advantage is that it is convenient for maintenance. The pump body, suction pipeline, discharge pipeline and motor are not moved during maintenance. It only needs to remove the intermediate coupling of the extension coupling to exit the rotor part for maintenance.

3. The shell of IY single-stage single-suction centrifugal oil pump (I. e. pump body and pump cover) constitutes the working room of the water pump. The impeller, shaft and rolling bearing are the rotor of the pump. The suspension bearing part supports the rotor part of the pump, and the rolling shaft bears the radial and axial forces of the pump.

4. IY single-stage single-suction centrifugal oil pump In order to balance the axial force of the pump, most pumps are equipped with sealing rings before and after the impeller, and balance holes are provided on the back cover of the impeller. Because some pumps have little axial force, There is no sealing ring and balance hole on the back of the impeller.

5. The axial sealing ring of IY single-stage single-suction centrifugal oil pump is composed of packing gland, packing ring and packing to prevent air intake or a large amount of water leakage. If the impeller of the pump is balanced, the cavity equipped with soft packing is connected with the suction port of the impeller. If the liquid at the inlet of the impeller is in a vacuum state, it is easy to enter the air along the surface of the shaft sleeve. Therefore, a packing ring is installed in the packing cavity. Through the small hole on the pump cover, the pressure water in the centrifugal pump chamber is led to the packing ring for sealing. If the impeller of the pump does not have a balance hole, the liquid pressure on the back of the impeller is greater than atmospheric pressure, so there is no air leakage problem, so the packing ring may not be installed.

6, single-stage water centrifugal pump in order to avoid shaft wear, in the shaft through the packing cavity is equipped with a shaft sleeve protection. O-ring between the shaft sleeve and the shaft to prevent air or water leakage along the mating surface.

7. The transmission mode is connected with the motor by lengthening the elastic coupling. The rotation direction of the pump is clockwise from the driving end.

Pump model description

For example: IY80-65-160A

IY-type single-stage single-suction centrifugal oil pump

80-Diameter of suction port (mm)

65-Discharge outlet diameter (mm)

160-Nominal diameter of impeller (mm)

-

Flow range: 6.3~400 m3/h

Head range: 8~125m

Conveying temperature:-20 ℃ ~ 150 ℃

Inlet pressure:< 0.8MPa

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

-

-

1. The following rechecks shall be made before the pump is in place

The size, position and elevation of the foundation shall meet the design requirements; the equipment shall be free of missing parts, damage and corrosion; the nozzle protector and plug cover shall be in good condition; the turning gear shall be flexible, free of blocking, jamming and abnormal sound.

2. Leveling and alignment of pump installation

The height of the pump foundation above the ground shall be convenient for the installation of the pump and shall not be less than 0.1m. After the water pump is transported to the designated position, the equipment shall be hoisted and installed, and it shall be accurately located on the basis of the prepared equipment, then the anchor bolts and nuts shall be put on, the shim iron shall be placed under the base, the level shall be preliminarily leveled, and the anchor bolts shall be filled with concrete. After the concrete solidification period expires, the foundation bolt cap shall be leveled and tightened, and each group of shim iron shall be fixed by spot welding. The foundation surface shall be roned and leveled with cement mortar after water washing.

3. The pipeline installation shall meet the following requirements

(1) The inside of the pipe and the pipe end should be cleaned, the sealing surface and thread should not be damaged, and the flange end surface or thread axis line connected with each other should be parallel and centered, and should not be forcibly connected. The weight of the pipeline should not be added to the water pump, and there should be respective supports.

(2) After the pipeline is connected with the pump, welding and gas cutting should not be carried out on it. If welding or gas cutting is required, the pipeline should be removed or necessary measures should be taken to prevent welding slag from entering the pump and damaging the pump parts. After the installation is completed, the pump shaft and impeller should be moved without friction or jamming, otherwise the pump should be disassembled to check the cause.

(3) The configuration of the pipeline should be rechecked according to the equipment data and design drawings.

(4) valves, check valves and pressure gauges shall be installed on the outlet pipe of each water pump; when the water pump pumps directly from the outdoor water supply network, valves, check valves and pressure gauges shall be installed on the suction pipe, and bypass pipes with valves shall be set up around the water pump.

-

1. Unable to start:If the pump cannot be started, first check whether the power supply is normal. Ensure that the power supply is well connected and check whether the motor protection device is triggered. If the power supply is normal, it may be due to damage to the pump bearing or stuck pump impeller. The solution is to replace the damaged bearing or clean the stuck impeller.

2. Flow reduction:If the flow of the pump decreases, it may be due to the inlet valve not opening or the outlet valve partially closing. Check the position of the valves and make sure they are open. In addition, check whether the suction pipe of the pump is blocked or leaked, which may affect the flow rate of the pump.

3. Excessive vibration or noise:Excessive pump vibration or noise may be caused by pump imbalance or bearing damage. Check the balance of the pump and make balance adjustments as needed. If the bearing is damaged, replace the damaged bearing.

4. Water leakage:If the pump has a water leakage problem, it may be caused by a damaged seal or a crack in the pump body. Check the seal of the pump and replace the damaged seal. If the pump body is found to be cracked, the entire pump body may need to be replaced.

5. Overheating:Pump overheating may be caused by excessive load or failure of the pump's cooling system. Check the load of the pump and ensure that the cooling system is working properly. If the load is too large, the operating parameters of the pump may need to be adjusted.

Previous Page

Next Page

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!