Recommend Products

Contact Us

| Email: | sales@sanchangpump.com |

| Hotline: | +86 133 0748 1676 |

| +86 193 1300 1794 | |

| Mobile: | +86 133 0748 1676 |

| Wechat: | +86 193 1300 1794 |

| Address: | No.517,Xiangfu Road |

| Yuhua District, | |

| Changsha City | |

| Hunan Province, P.R.C |

ISG vertical single-stage pipeline centrifugal pump

Classification:

ISG vertical single-stage pipeline centrifugal pump

Urban water supply

Pipeline Pump

ISG vertical single-stage pipeline centrifugal pump

Key words:

water pump

Head range: H = 5~125m

Conveying temperature:-20-150 ℃ (please declare above 80 ℃)

Inlet pressure: 0-7.5MPa (above 0.3 MPa, please declare)

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

Hotline:

- Product Description

- Performance Parameter

- Installation Drawings

- Installation And Use

- Faults And Solutions

-

- Commodity name: ISG vertical single-stage pipeline centrifugal pump

Flow range: Q = 5.6~720 m3/h<br>Head range: H = 5~125m<br>Conveying temperature:-20-150 ℃ (please declare above 80 ℃)<br>Inlet pressure: 0-7.5MPa (above 0.3 MPa, please declare)<br>Sealing form: packing seal, mechanical seal<br>Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc</br></br></br></br></br>

Product Description

ISG vertical pipeline centrifugal pump is an excellent hydraulic model selected by the scientific and technical personnel of this unit and the domestic pump experts, and the performance parameters of IS centrifugal pump are adopted, which are cleverly combined and designed on the basis of general vertical pump. At the same time, according to the use of temperature, media and other different in the ISG type based on the development of applicable hot water, high temperature, corrosive chemical pump, oil pump. This series of products have the advantages of high efficiency, energy saving, low noise and reliable performance.

In line with the latest national machinery department JB/T53058-93 standard requirements, products according to international ISO2858 standards design and manufacturing.

Overview

ISG type vertical management centrifugal pump is used for conveying clear water and other liquids with physical and chemical properties similar to clear water. it is suitable for industrial and urban water supply and drainage, pressurized water supply for high-rise buildings, garden sprinkler irrigation, fire fighting pressurization, long-distance transportation, heating, ventilation and refrigeration cycle, bathroom and other cold and warm water cycle pressurization and equipment matching. the operating temperature is t <80 ℃.

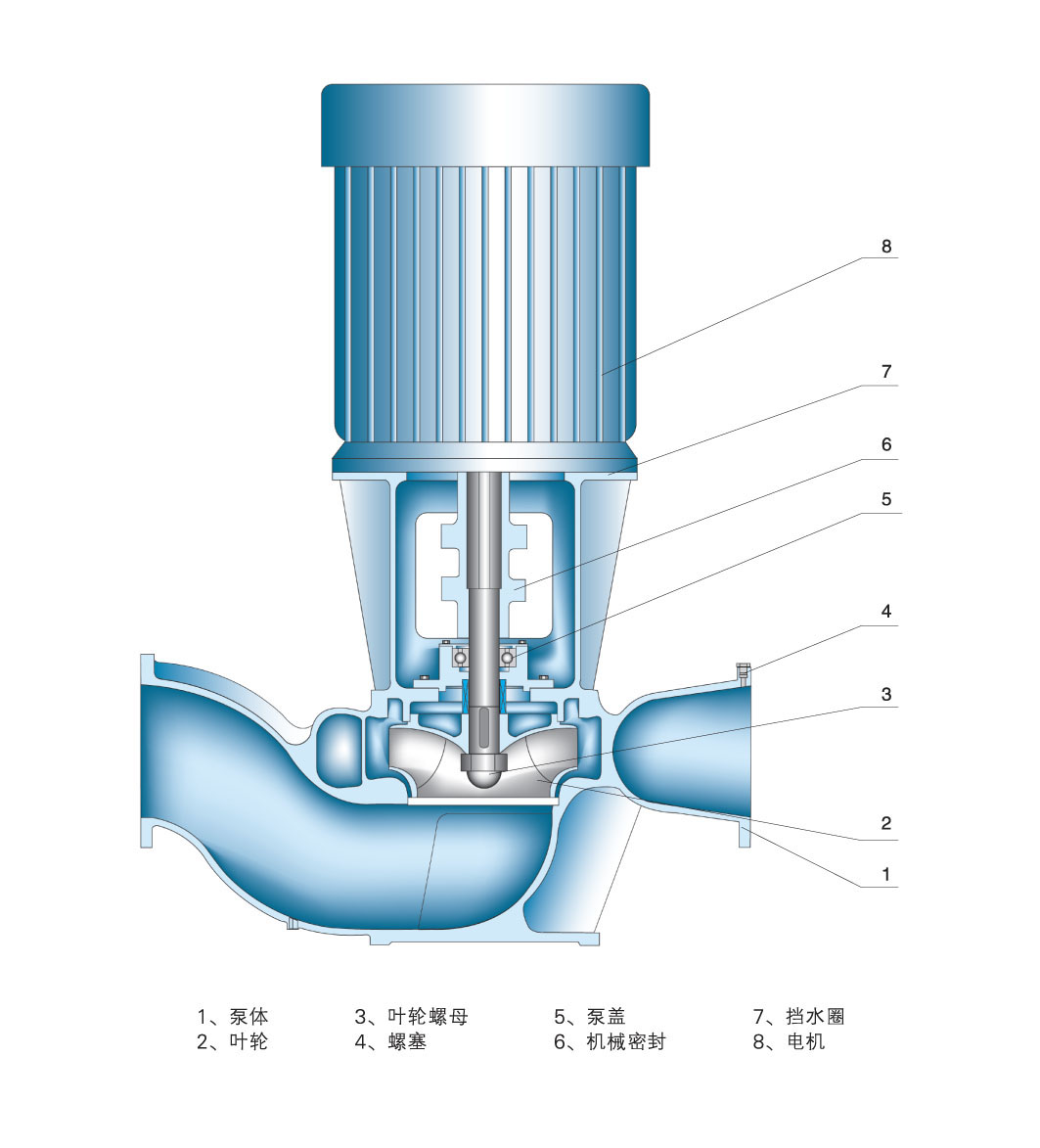

Structure Description

1. The pump is of vertical structure, with the same import and export caliber and located on the same center line. It can be installed in the pipeline like a valve. It has compact and beautiful appearance, small floor space and low construction investment. If a protective cover is added, it can be placed outdoors.

2. The impeller is directly installed on the extended shaft of the motor, with short axial size, compact structure, reasonable bearing configuration of the pump and the motor, which can effectively balance the radial and axial loads generated by the pump operation, thereby ensuring the smooth operation of the pump. Low vibration and low noise.

3. The shaft seal adopts mechanical seal or mechanical seal combination, imported titanium alloy sealing ring, medium-sized high temperature resistant mechanical seal and hard alloy material, wear-resistant seal, which can effectively extend the service life of mechanical seal.

4, easy installation and maintenance, no need to disassemble the pipeline system, as long as the pump union seat nut can be pulled out all the rotor parts.

5. The series and parallel operation mode of the pump can be adopted according to the requirements of the use, that is, the flow and head.

6. The vertical and horizontal installation of the pump can be used according to the requirements of the pipeline layout.

Use

ISG type vertical hot water pipeline pump is suitable for metallurgy, chemical industry, textile, wood processing, papermaking and restaurants, bathrooms, hotels and other boilers high temperature hot water pressurized circulation transmission and urban housing heating circulation pump, the use of temperature below 80 ℃.

Model Description

Example: ISG50-160(I)A(B)

50-diameter of pump inlet and outlet is 50mm

160-nominal outer diameter of impeller is 160mm

I-Flow Classification

A- impeller outer diameter cutting code

B- Impeller through the second cut

ISG-Single Stage Single Suction Pipeline Centrifugal Pump

Example: ISGD50-160(I)A(B)

50-diameter of pump inlet and outlet is 50mm

160-nominal outer diameter of impeller is 160mm

I-Flow Classification

A- impeller outer diameter cutting code

B- Impeller through the second cut

ISGD-Low Speed Vertical Pipeline Centrifugal Pump

-

Flow range: Q = 5.6~720 m3/h

Head range: H = 5~125m

Conveying temperature:-20-150 ℃ (please declare above 80 ℃)

Inlet pressure: 0-7.5MPa (above 0.3 MPa, please declare)

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

-

-

Starting and running:

1, turn the motor fan blade by hand, the impeller should be no jarring phenomenon, flexible rotation.

2. Turn the pump by hand to make the lubricating liquid enter the end face of the mechanical seal.

3. Irrigation and exhaust, open the inlet valve to make the liquid fully enter the pump cavity until the entire pipeline is filled with liquid, and ensure the sealing of the inlet pipeline.

4. Close the outlet valve to reduce the starting current.

5. Turn on the power supply, start to determine the correct running direction, and rotate clockwise from the fan blade end of the motor.

6, gradually adjust the opening of the outlet valve, try to make the pump work in the rated state.

7. During the operation of the pump, if noise or unusual sounds are found, stop and check immediately.

8, the normal mechanical seal leakage should be less than 3 drops/min, check the motor, bearing temperature rise <70 ℃, more than this value should check the reason.

Stop:

1. Close the valve of the discharge pipeline.

2. Cut off the power supply and stop the motor running.

3. Close the inlet valve.

4. If the pump is stopped for a long time, the liquid in the pump should be drained.

-

Fault phenomenon

Cause of failure

Exclusion method

1. The water pump does not produce water

a. The inlet and outlet valves are not opened, the inlet and outlet pipelines are blocked, and the runner impeller is blocked.

B, the motor running direction is wrong, the motor phase loss speed is very slow.

C, suction pipe leakage.

D, the pump is not filled with liquid, there is air in the pump cavity.

E, the inlet water supply is insufficient, the suction is too high, the bottom valve leaks.

F, pipeline resistance is too large, pump selection is improper.

A, check, remove the blockage.

B, adjust the direction of the motor, tighten the motor wiring.

C, tighten the sealing surface, eliminate air leakage.

D, fill the liquid and open the exhaust valve, exhaust air.

E, shut down, check, adjust (grid water pipe or with suction range use prone to this phenomenon).

F, reduce the pipeline curve, re-select the pump.

2. Insufficient water pump flow

A, first press 1. reason inspection.

B, pipe, pump flow impeller part of the blockage, scale accumulation, valve opening is insufficient.

C, low voltage.

D, impeller wear.

A, first press 1. exclude.

B, remove the blockage, re-adjust the valve opening.

C, voltage stabilization.

d. Replace the impeller.

3. Excessive power

A, exceed the rated flow use.

B, suction is too high.

C, pump bearing wear.

A, adjust the flow, close the small outlet valve.

B. reduced.

c. Replace the bearing.

4. Vibration of noise

a. Unstable pipeline support.

B, liquid mixed with gas.

C, produce cavitation.

D, bearing damage.

E, motor overload heating operation.

a. Stabilize the pipeline.

B, increase the suction pressure exhaust.

C, reduce the vacuum degree.

d. Replace the bearing.

e. Adjust by 5.

5. Motor heating

A, excessive flow, overload operation.

B, touch.

C, motor bearing damage.

d. Insufficient voltage.

a. Close the outlet valve.

B. Check and exclude.

c. Replace the bearing.

d. Voltage stabilization.

6. Water leakage of water pump

A, mechanical seal wear.

B, the pump body has sand hole or rupture.

C, the sealing surface is not smooth.

d. Loose installation bolts.

a. replacement.

B, welding repair or replacement.

c. Finishing.

d. Fastening.

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!