Why is one of the three multi-stage pumps hot when started?

Category: Water pump knowledge

2025-08-20

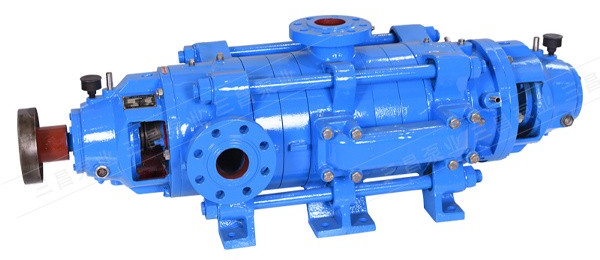

In industrial production, multistage pumps are widely used in various liquid transport systems due to their efficient and stable performance. However, during actual operation, there is sometimes a puzzling issue: when three identical multistage pumps are started simultaneously, one of the pumps exhibits abnormal heating. This phenomenon not only affects production efficiency but may also cause damage to the equipment.

1. Issues with the equipment itself

First, we need to consider whether there are defects or faults in the equipment itself. Although the three pumps are of the same model, there may inevitably be slight differences during the manufacturing and assembly process. These differences may manifest in aspects such as the material of the pump body, the quality of the seals, and the precision of the bearings. In particular, the bearings, as key components of the multistage pump, directly affect the overall performance of the pump. If one pump has issues such as wear, looseness, or poor lubrication in its bearings, excessive friction heat will be generated during high-speed operation, leading to an increase in the pump body temperature.

In addition, the internal structure of the pump body may also affect the heat dissipation effect. For example, if the cooling water passage of the pump body is poorly designed, or if there are blockages in the passage, it will affect the circulation of the coolant, thereby reducing the heat dissipation efficiency. In this case, even if the external cooling conditions are good, the pump body temperature may still continue to rise.

2. Mismatch of operating parameters

In addition to issues with the equipment itself, the mismatch of operating parameters is also an important reason for the heating of the pump body. In practical applications, the operating conditions of each pump may vary. For example, parameters such as flow rate, head, and speed may be adjusted due to changes in actual conditions. If the operating parameters of one pump are set unreasonably, such as a speed that is too high while the flow rate is too low, it will lead to poor internal liquid flow, generating eddies and localized overheating.

Moreover, the properties and temperature of the liquid can also affect the pump's heat dissipation effect. If the liquid being transported has a high viscosity or contains impurities, it will increase the friction resistance inside the pump, generating more heat. At the same time, if the liquid temperature is too high, it will also reduce the heat dissipation capacity of the pump body, causing the pump body temperature to rise further.

3. Inadequate installation and maintenance

Inadequate installation and maintenance is also a factor that cannot be ignored in the heating of the pump body. During installation, if the pump's axis is misaligned, the anchor bolts are unevenly tightened, or the foundation is unstable, it will cause vibration and noise during operation, exacerbating the wear of bearings and seals, and generating excessive heat.

In terms of maintenance, if the bearings, seals, and other wear-prone parts of the pump are not regularly checked and replaced, or if the cooling system is not cleaned and maintained, the performance of these components will gradually decline, affecting the pump's heat dissipation effect. In particular, the lubrication of the bearings, if the lubricant deteriorates or is insufficient, will exacerbate the wear and heating of the bearings.

4. Impact of environmental factors

Finally, we also need to consider the impact of environmental factors on the pump body temperature. For example, if the ventilation in the pump room is poor or the temperature is too high, it will reduce the heat dissipation efficiency of the pump body. Additionally, if there are strong magnetic fields or electromagnetic interference around the pump room, it may also affect the pump's electronic control system, leading to unstable operation or overheating of the pump.

In summary, the reasons for one of the three multistage pumps heating up may involve multiple aspects such as the equipment itself, operating parameters, installation and maintenance, and environmental factors. To address this issue, we can take the following approaches: first, strengthen daily maintenance and care of the equipment to ensure that all components are in good working condition; second, reasonably set and adjust operating parameters to match the pump's operating conditions with actual needs; third, optimize the environmental conditions of the pump room to improve ventilation and heat dissipation efficiency; fourth, regularly inspect the pump and troubleshoot to promptly identify and address potential issues.

RELATED INFORMATION

2025/08/22

2025/08/21

Recommend Products

Contact Us

Free Hotline:0086-13307481676

Fixed telephone:0086-13307481676

Mobile:0086-13307481676(WeChat)

E-mail:sales@sanchangpump.com