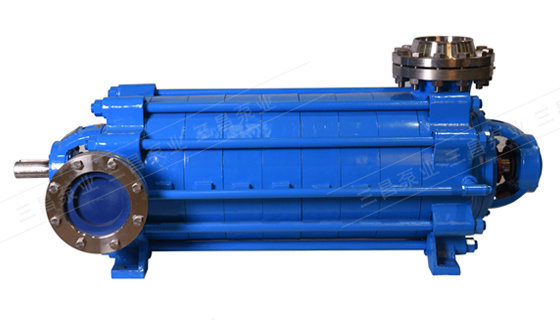

How to add water to a light stainless steel multistage centrifugal pump

Category: Water pump knowledge

2025-09-01

When a light stainless steel multistage centrifugal pump is used for the first time, restarted after a long period of inactivity, or has excessive air inside (such as failing to draw water), it is necessary to perform water filling and air venting operations to ensure the pump operates normally. This ensures the pump is fully filled with water and air is expelled, preventing equipment damage caused by water shortage and guaranteeing efficient pump operation.

I. Preparation before adding water

Check equipment status

1. Ensure the pump power is disconnected to avoid safety accidents caused by misoperation.

2. Check whether the pump body and pipeline connections are tight and if there are any leaks; check if seals (such as mechanical seals) are intact.

3. Confirm that the suction pipeline (such as foot valve, filter) is not blocked and the suction lift is within the pump's rated range (usually suction lift ≤ 8 meters for light pumps).

Prepare tools

Funnel (to facilitate pouring water into the filling port).

Clean water (avoid using water containing impurities or corrosive substances to prevent damage to internal pump parts).

II. Specific steps for adding water

1. Locate the water filling port

The water filling port of a light stainless steel multistage centrifugal pump is usually located on top of the pump body near the pump cover. It appears as a threaded hole and may be equipped with a plastic or metal plug (in some pumps, the air vent and water filling port are the same).

2. Open the water filling port and air vent

Unscrew the plug of the water filling port. If the pump body has a separate air vent valve (such as a small screw or ball valve), open it simultaneously to expel air inside the pump.

If there is no separate air vent, loosen the valve on the outlet pipeline (such as a gate valve) to serve as a temporary air vent.

3. Slowly add water

Align the funnel with the water filling port and slowly pour clean water, observing the water level rise.

When water flows continuously from the air vent (or outlet valve) without bubbles, it indicates that the air inside the pump has been expelled. At this point, stop adding water.

4. Close the air vent and water filling port

First tighten the air vent valve or outlet pipeline valve, then securely screw the water filling port plug to ensure a tight seal and prevent water leakage.

5. Trial operation check

Turn on the power and start the pump. Observe whether the water discharge is smooth and if there is any abnormal noise or vibration.

If the water discharge is normal, the water filling is successful; if the pump still fails to draw water or there is abnormal noise, recheck whether the air venting is complete or if there is air leakage in the pipeline.

III. Precautions

1. Prohibit dry running

If water is not added or air venting is incomplete, friction between the impeller and casing will cause mechanical seal overheating and damage, possibly burning out the motor. Ensure the pump chamber is fully filled with water before starting.

2. Regularly check water level

If the pump is unused for a long time, check the water level inside the pump before reuse. If the water level is insufficient, add water.

3. For self-priming multistage pumps

Some light pumps are designed as self-priming. Water must be added initially (called "priming"). Subsequent use can rely on the self-priming function to draw water, but ensure the suction pipeline has no air leaks, or the self-priming effect will be affected.

4. Handling special situations

If water cannot be discharged after adding water, there may be air leakage in the suction pipeline (such as loose joints) or failure of the foot valve (unable to seal one-way). Check and repair before adding water again.

If the pump body leaks water, replace the seals before performing the water filling operation again.

RELATED INFORMATION

2025/08/22

2025/08/21

Recommend Products

Contact Us

Free Hotline:0086-13307481676

Fixed telephone:0086-13307481676

Mobile:0086-13307481676(WeChat)

E-mail:sales@sanchangpump.com