How do self-balancing pumps in the salt chemical industry adapt to the long-term operation of media with high solids content?

Category: Water pump knowledge

2025-08-15

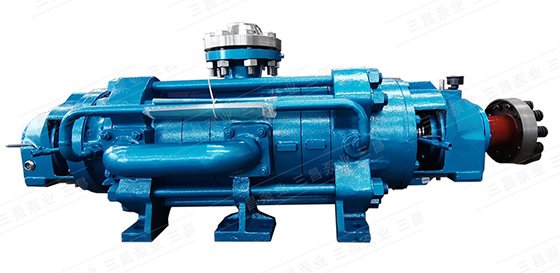

In the salt chemical industry, high solid content media particularly exacerbate pump wear, clogging, and corrosion issues. Self-balancing multi-stage centrifugal pumps, which eliminate the balance disc device of traditional multi-stage pumps and achieve axial force self-balancing through symmetrical impeller arrangement, are structurally more suitable for harsh conditions. The core logic for their long-term operation with high solid content media is: "Wear resistance, anti-clogging, corrosion resistance, and vibration reduction."

I. Material Optimization: Targeted Solutions for Wear and Corrosion

The core damage caused by high solid content media in the salt chemical industry is: "Particle erosion wear" and "Salt solution corrosion." It is necessary to select materials that have both wear resistance and corrosion resistance. The design of key components (flow parts) is as follows:

1. Impellers, pump casings, and other flow parts

Prioritize the use of high-chromium cast iron (such as Cr26): With a chromium content of over 26%, it forms a dense Cr₂O₃ oxide film, which is resistant to salt solution corrosion, and has a hardness of HRC60 or higher, providing strong resistance to particle erosion wear (with a lifespan 3-5 times that of ordinary cast iron), suitable for salt slurry with medium to low solid content (≤15%).

High solid content (>15%) or high flow rate scenarios: Use duplex stainless steel (such as 2205) + tungsten carbide coating: Duplex steel (austenite + ferrite) is resistant to chloride ion corrosion (anti-stress corrosion cracking), and the surface is coated with 3-5mm of tungsten carbide (hardness HRC70 or higher) to further enhance wear resistance, suitable for mother liquor transportation with more salt crystal particles.

Extreme conditions (such as fluorine-containing salt media): Use Hastelloy C276, which is resistant to strong corrosion but expensive, and is only used in special scenarios.

2. Shafts and shaft sleeves

The shaft is made of 42CrMo alloy quenched and tempered steel (surface chrome-plated or nitrided) to increase surface hardness (HV800 or higher), providing resistance to scratches and wear.

The shaft sleeve is made of silicon carbide (SiC) or silicon nitride ceramic, which has high hardness and a low friction coefficient, reducing shaft wear caused by particle jamming.

II. Structural Design: Reducing Clogging and Wear Risks

The symmetrical impeller structure of the self-balancing pump itself reduces the wear of axial force-related components. Based on this, further optimization is carried out for high solid content media:

1. Flow Channel "No Dead Angle, Large Flow" Design

The impeller adopts an open or semi-open structure (without front and rear cover plates or only retaining the rear cover plate), and the flow channel width is increased by 20%-30% compared with ordinary closed impellers to avoid particles staying and accumulating in the flow channel (especially suitable for easily crystallizing salt media).

The pump casing flow channel adopts a gradual rounded transition, eliminating right-angle or acute-angle structures to reduce liquid turbulence and particle impact (turbulence will aggravate local wear, such as at the pump casing inlet and impeller outlet).

The impeller inlet diameter is increased (10%-15% larger than ordinary designs) to reduce the inlet flow rate (controlled at 1.5-2.5m/s), reducing particle erosion of the impeller inlet.

2. Strengthening of Symmetrical Impeller Layout

The self-balancing pump offsets axial force through the "first-stage impeller + secondary impeller reverse symmetrical arrangement", eliminating the need for a balance disc (the gap between the traditional balance disc and the shaft sleeve is easily jammed by particles, leading to balance failure).

3. Inlet and Outlet Pipe Adaptation Design

A conical filter (filter mesh size 5-10mm) is installed on the inlet pipe to intercept large particle impurities (such as salt blocks, scale hard blocks) to prevent them from entering the pump and jamming the impeller.

A backflow prevention valve is installed on the outlet pipe to prevent media backflow from scouring the impeller when the machine is shut down (salt slurry backflow can cause the impeller to reverse, exacerbating wear).

III. Sealing System: Preventing Leakage and Particle Intrusion

High solid content media easily enters the sealing surface, leading to wear. The self-balancing pump needs to optimize the sealing design in a targeted manner:

1. Mechanical Seal Selection

Use an externally mounted metal bellows mechanical seal: The bellows material is Hastelloy or duplex steel, and the sealing surface is made of silicon carbide (SiC) against graphite (resin-impregnated), which is wear-resistant and has a low friction coefficient.

Increase the flushing scheme: Use API Plan 11 (self-flushing) + Plan 52 (pressure buffer tank) to continuously flush the sealing cavity with clean desalinated water or process media (after filtration) to flush particles away from the sealing surface and cool the sealing components at the same time (salt media is prone to crystallization at high temperatures, and flushing can prevent crystallization blockage).

2. Auxiliary Sealing Components

The static ring seal ring is made of fluororubber (FKM) or perfluoroelastomer (FFKM), which is resistant to salt corrosion and temperature (-20℃~200℃), avoiding the failure of ordinary nitrile rubber due to swelling by salt solution.

IV. Operation and Maintenance Strategies: Guaranteeing Extended Life

Even with design optimization, damage still needs to be reduced through operation control and maintenance:

1. Operating Parameter Control

Avoid "low flow, high head" operation: When deviating from the design conditions, the liquid in the pump is prone to backflow and eddy currents, which aggravate the erosion of particles on the impeller and pump casing (it is recommended to control the operating flow within 70%-110% of the design flow).

Control the media temperature: Salt media (such as sodium chloride solution) is prone to crystallization at high temperatures (>80℃), and the media temperature needs to be controlled below the crystallization point through jacket cooling or a temperature control system (such as a sodium chloride solution temperature ≤60℃) to prevent crystal particles from blocking the flow channel.

Maintain a stable inlet liquid level: If the inlet liquid level is too low, "cavitation" is likely to occur. The impact force generated when the bubbles burst will accelerate impeller wear. It is necessary to ensure that the inlet tank liquid level is ≥1.5m (or controlled by liquid level interlock).

2. Regular Maintenance and Monitoring

Daily check: Monitor pump body vibration (≤4.5mm/s), bearing temperature (≤70℃), and seal leakage (≤5 drops/minute). If abnormalities occur, stop the machine immediately for troubleshooting (excessive vibration can exacerbate impeller imbalance and wear, and excessive temperature may indicate bearing or seal failure).

Regular disassembly and inspection: Every 1000-1500 hours of operation (adjust according to solid content), disassemble the pump body to check the wear of the impeller and pump casing (focus on the edge of the impeller blades and the outlet of the pump casing flow channel). Repair or replace when the wear exceeds 1mm (tungsten carbide welding can be used to repair the impeller).

Impeller balance correction: The replaced or repaired impeller needs to be subjected to a dynamic balance test (G6.3 level or above) to avoid vibration and extra wear caused by imbalance.

Clean flow channels: When shutting down, use high-pressure water (or process solvent) to flush the flow channels inside the pump to remove residual salt crystals and particle accumulation to prevent pump jamming during the next start-up.

RELATED INFORMATION

2025/08/22

2025/08/21

Recommend Products

Contact Us

Free Hotline:0086-13307481676

Fixed telephone:0086-13307481676

Mobile:0086-13307481676(WeChat)

E-mail:sales@sanchangpump.com