Why do self-balancing pumps need to be inspected and maintained regularly?

Category: Water pump knowledge

2025-08-14

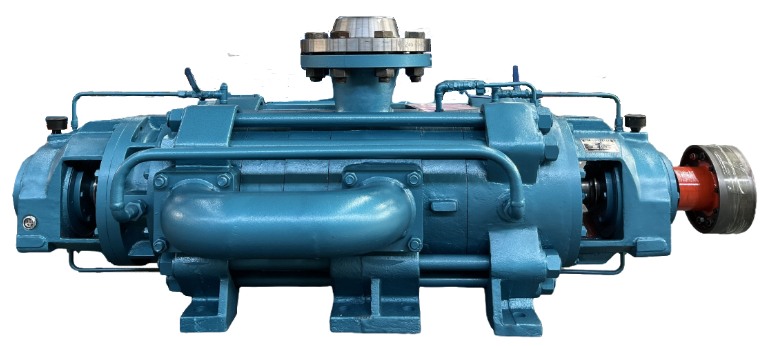

As an efficient, balance-disk-free multistage pump, the stable operation of the self-balancing pump depends on precise structural coordination and complex working condition adaptability. Its complex structure and harsh working conditions determine that regular inspection and maintenance must be carried out to offset medium damage, maintain structural accuracy, prevent sudden failures, and ultimately achieve the goals of stable operation, ensuring production safety, and reducing comprehensive costs.

I. Offset the continuous damage of the medium to the core components

Self-balancing pumps are mostly used to transport complex media such as corrosive, particle-containing, high-temperature and high-pressure media (such as chemical slurries, salt water, steam condensate, etc.). These media will cause continuous damage to the key components of the pump:

(1) Corrosion

Media such as acids, alkalis, and salt solutions will cause electrochemical or chemical corrosion to metal parts such as impellers, pump casings, and shaft sleeves, resulting in pitting, cracks, and even perforations on the surface of the parts (such as "intergranular corrosion" of stainless steel by chloride ions), which affects the sealing performance and hydraulic efficiency of the pump.

(2) Wear and blockage:

Media containing solid particles will scour the impeller blades and flow channels, causing the blades to become thinner and the flow channels to deform, destroying the "self-balancing" characteristics of the pump (the balance accuracy of the symmetrically arranged impellers); at the same time, particles may accumulate at the impeller inlet and sealing gap, leading to increased pump vibration and abnormal current increase.

(3) High-temperature aging:

High-temperature media will accelerate the aging and hardening of seals (such as the moving/stationary rings of mechanical seals, O-rings), resulting in seal failure and media leakage; at the same time, high temperature will reduce the viscosity of lubricating oil, affecting bearing lubrication, and may cause bearing overheating and burnout.

Regular inspections can detect these damages in time (such as the degree of impeller corrosion, the aging state of seals), and avoid the expansion of failures by repairing (such as welding the impeller) or replacing parts (such as wear-resistant impellers, high-temperature-resistant seals).

II. Maintain the stability of the "self-balancing" core performance

The core advantage of the self-balancing pump is to achieve self-balancing of axial force through symmetrically arranged impellers, intermediate sections and other structures, without the balance disc of traditional multi-stage pumps, but its balance performance depends on the precise cooperation of each component:

1. If a certain stage of the impeller has a mass deviation due to wear/corrosion (such as uneven weight), or the shaft system is bent due to long-term operation or the bearing clearance is too large, it will destroy the symmetrical balance of the impeller, resulting in axial force imbalance, causing severe vibration of the pump body, and even causing friction and collision between the impeller and the pump casing.

2. If the assembly accuracy (such as concentricity) of static parts such as the middle section and guide vane is loosened due to vibration, it will change the medium flow path, reduce the hydraulic efficiency of the pump, and even aggravate local turbulence and wear.

3. Regular maintenance (such as measuring the radial runout of the shaft, checking the impeller balance accuracy, and re-tightening the middle section bolts) can calibrate these deviations in time, ensure that the "self-balancing" structure remains effective, and avoid chain failures caused by imbalance.

III. Ensure production continuity and safety, and reduce comprehensive costs

Avoid unplanned shutdowns: Self-balancing pumps are mostly "key node equipment" in the production process. If they suddenly shut down due to component damage, it will lead to the interruption of medium transportation and cause subsequent processes to stagnate (such as chemical reaction material interruption, heating system water circulation stoppage), resulting in output loss; after the shutdown, the medium in the pipeline may crystallize and solidify (such as high-temperature slurry solidifying after cooling), and additional manpower is required to clean up to restore production.

Prevent safety accidents: Medium leakage (such as corrosive medium leakage) may cause equipment corrosion, personal injury, and even cause fire and explosion (such as flammable and explosive media); if excessive pump body vibration is not handled in time, it may cause the pump and pipeline connection to break, expanding the scope of the accident.

Extend equipment life: If small faults (such as slight leakage, abnormal bearing noise) are ignored, they will gradually deteriorate into major faults (such as shaft breakage, pump casing cracking), and the maintenance cost will skyrocket from hundreds of yuan (replacing seals) to tens of thousands of yuan (replacing the entire machine); regular maintenance through "early detection and early repair" can significantly extend the overall life of the equipment and reduce long-term investment.

RELATED INFORMATION

2025/08/22

2025/08/21

Recommend Products

Contact Us

Free Hotline:0086-13307481676

Fixed telephone:0086-13307481676

Mobile:0086-13307481676(WeChat)

E-mail:sales@sanchangpump.com