Differences between D/DG/DF/DY/MD type horizontal multistage centrifugal pumps

Category: Water pump knowledge

2025-08-14

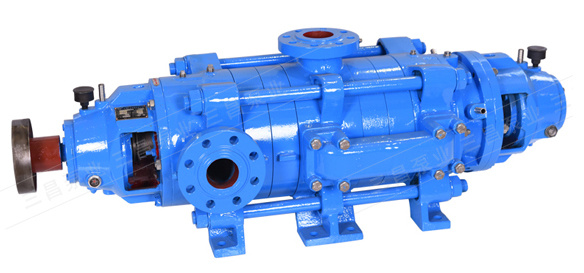

Horizontal multistage centrifugal pumps are divided into D, DG, DF, DY, and MD types. There are many types. We can distinguish the models from four dimensions: core characteristics, conveying medium, structure and materials, and applicable scenarios.

1. D-type horizontal multistage centrifugal pump

Full name: Horizontal multistage clear water centrifugal pump

Core features: The most basic horizontal multistage pump, designed to transport clean water and clean liquids with physical and chemical properties similar to clean water (such as those without particles, non-corrosive, and with viscosity close to water).

Transporting medium: clean water, tap water, softened water, etc., medium temperature ≤80℃ (normal temperature).

Structure and material: The flow passage parts (impeller, pump casing, etc.) are mostly made of cast iron (ordinary working conditions) or cast steel (slightly higher pressure), and the cost is low. It adopts packing seal or mechanical seal, which has simple structure and convenient maintenance.

Applicable scenarios: Low-corrosion, normal-temperature clean liquid transportation such as urban tap water pressurization, mine underground drainage (clean water), agricultural irrigation, and industrial circulating water systems.

2. DG-type horizontal multistage centrifugal pump

Full name: Horizontal multistage boiler feed water pump

Core features: Designed for boiler feed water, it adapts to high temperature and high pressure conditions, emphasizing the "high temperature cleanliness" of the medium.

Transporting medium: Boiler feed water (soft water), high-temperature clean water, medium temperature is usually 105-250℃ (some models can reach above 400℃, need to be equipped with high-temperature seals)

Structure and material: The flow passage parts are made of high-temperature resistant materials (such as high-quality carbon steel, chromium-molybdenum steel) to avoid the decrease of material strength at high temperatures. The shaft seal adopts high-temperature resistant mechanical seal or labyrinth seal to prevent high-temperature medium leakage; the gap between the impeller and the pump casing is designed more strictly to reduce the thermal expansion effect at high temperatures. The pump shaft is thickened, and the bearing adopts high-temperature resistant rolling bearing to adapt to the stability under high-temperature conditions.

Applicable scenarios: High-pressure (head usually 100-2000m) and high-temperature clean liquid transportation such as power plant steam boiler feed water, industrial boiler make-up water, and high-temperature hot water circulation systems.

3. DF-type horizontal multistage centrifugal pump

Full name: Horizontal multistage corrosion-resistant centrifugal pump

Core features: Designed for corrosive media, emphasizing the corrosion resistance of flow passage parts.

Transporting medium: Various corrosive liquids, such as acids (sulfuric acid, hydrochloric acid), alkalis (sodium hydroxide solution), salt solutions, chemical slurries, etc. (without large particles of impurities to avoid abrasive corrosion of parts).

Structure and material: The flow passage parts are selected according to the corrosiveness of the medium: stainless steel (304, 316) for mild corrosion; Hastelloy, titanium alloy or lined plastic/lined rubber for strong corrosion. The sealing parts are made of chemically resistant materials (such as fluororubber, polytetrafluoroethylene) to avoid being corroded by the medium. The impeller is designed to be smoother to reduce the retention of the medium in the pump and reduce the risk of local corrosion.

Applicable scenarios: Corrosive liquid transportation in chemical production processes, pharmaceutical industry, electroplating wastewater treatment, seawater desalination, etc.

4. DY-type horizontal multistage centrifugal pump

Full name: Horizontal multistage centrifugal oil pump

Core features: Designed for transporting oil media, emphasizing sealing performance and leak prevention, adapting to the low viscosity (or medium viscosity) characteristics of oils.

Transporting medium: Mineral oils or animal and vegetable oils such as gasoline, diesel, kerosene, lubricating oil, hydraulic oil, etc., the medium viscosity is usually ≤120cSt (special design is required for high viscosity), without hard particles (to avoid abrasive seals).

Structure and material: The flow passage parts are mostly made of cast iron and cast steel (to adapt to the non-corrosive or weakly corrosive characteristics of oils), and some models are made of stainless steel (for oils containing a small amount of water). The shaft seal adopts mechanical seal (with oil-resistant rubber) or magnetic seal to strictly prevent oil leakage (oil is easy to volatilize and flammable, and the leakage risk is high). The impeller has high balance accuracy to reduce operating vibration (oil has good lubricity, but the fit between the pump shaft and the bearing needs to adapt to the oil viscosity).

Applicable scenarios: Oil transportation in oil fields, process flow in refineries, oil storage and transportation in gas stations, lubricating oil circulation in the machinery industry, etc.

5. MD-type horizontal multistage centrifugal pump

Full name: Horizontal multistage mining wear-resistant centrifugal pump

Core features: Designed for sewage or mud containing solid particles, emphasizing the wear resistance of flow passage parts.

Transporting medium: Underground drainage of mines such as coal mines and metal mines (containing particles such as coal slag and sediment, particle diameter usually ≤10mm), industrial wastewater (containing a small amount of impurities), etc.

Structure and material: The flow passage parts (impeller, pump casing, guide vane) are made of wear-resistant materials such as high-chromium cast iron and wear-resistant alloy cast iron, with high surface hardness (above HRC50) to resist particle erosion and wear. The impeller is designed as semi-open or closed (with wear-resistant cover plate) to reduce the risk of particle blockage; the flow channel is wider to adapt to the flow of media containing impurities. The seal adopts wear-resistant mechanical seal or packing seal (with wear-resistant packing) to prevent particles from entering the shaft seal and causing wear.

Applicable scenarios: High-head transportation of media containing particles such as underground drainage of coal mines, drainage of metal mines, drainage of tunnel construction, and sewage transportation of sand and gravel plants.

RELATED INFORMATION

2025/08/22

2025/08/21

Recommend Products

Contact Us

Free Hotline:0086-13307481676

Fixed telephone:0086-13307481676

Mobile:0086-13307481676(WeChat)

E-mail:sales@sanchangpump.com