Recommend Products

Contact Us

| Email: | sales@sanchangpump.com |

| Hotline: | +86 133 0748 1676 |

| +86 193 1300 1794 | |

| Mobile: | +86 133 0748 1676 |

| Wechat: | +86 193 1300 1794 |

| Address: | No.517,Xiangfu Road |

| Yuhua District, | |

| Changsha City | |

| Hunan Province, P.R.C |

N type/NBA type horizontal centrifugal condensate pump

Classification:

Condensate pump

NBA type condensate pump

N type horizontal centrifugal condensate pump

Electric power industry

Key words:

water pump

Head: 12-170m

Power: 3-75kw

Cavitation allowance: 0.65-10.3m

Hotline:

- Product Description

- Performance Parameter

- Installation Drawings

- Installation And Use

- Faults And Solutions

-

- Commodity name: N type/NBA type horizontal centrifugal condensate pump

Flow rate: 5-137 m/h<br>Head: 12-170m<br>Power: 3-75kw<br>Cavitation allowance: 0.65-10.3m</br></br></br>

Product Description

N, NB, NBA type pump, is a single stage single suction cantilever centrifugal condensate pump. GN, GNL type pump, is a two-stage single suction centrifugal condensate pump, suitable for power plants, used to pump the condensate in the condenser and 750 ~ 3000kw steam turbine generator set pumping condensate or physical and chemical properties similar to water for other liquids.

Overview

N, NB, NBA type single stage single suction cantilever centrifugal condensate pump. The pump has good suction performance, suitable for power plants, for thermal power plants to transport condensate. The liquid temperature shall not exceed 80 ℃, and the pump inlet pressure shall not be higher than 0.6MPa.

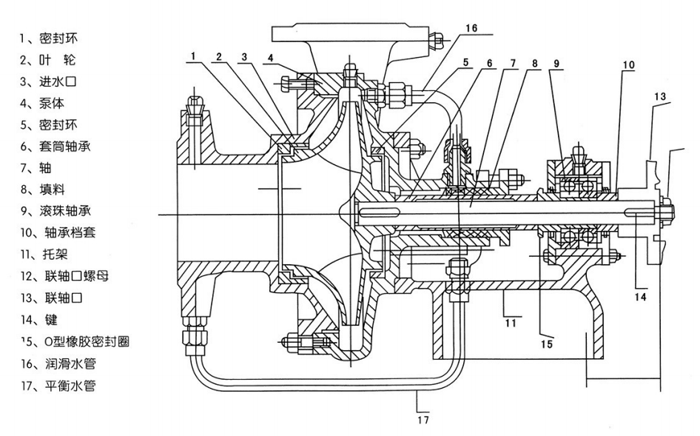

Structure Description

NB, NBA, GN, N type is horizontal, GNL is vertical. Using rolling bearings, grease lubrication, shaft seal for packing seal, also available mechanical seal.

Rotation direction: from the motor end, the pump rotates counterclockwise.

Material of main parts: the pump body, pump cover, sealing ring and shaft sleeve of the pump are made of cast iron, the impeller of N-type condensate pump is made of silicon brass, and the inducer is made of aluminum iron bronze. The shaft is made of high quality carbon steel.

Complete range: complete supply pump, motor, coupling, check valve, gate valve.

Use

It is suitable for the condensation of secondary steam generated by evaporation and concentration of various materials, and is widely used in many fields such as scientific research laboratories and even industrial production.

Model Description

100N-45

100-pump inlet caliber (mm)

N-condensate pump

B- suspension type

45-Design head of pump m

-

Flow rate: 5-137 m/h

Head: 12-170m

Power: 3-75kw

Cavitation allowance: 0.65-10.3m

-

-

Installation of 1. pump

1. Check the pump and motor after unpacking. If it is confirmed that there is no damage and loosening of fastening connectors caused by loading, unloading and transportation, the inlet and outlet covers of the pump are intact, and no dirt enters the pump, it can be directly sent to the use site for installation.

2. The foundation plane on which the pump is installed shall be leveled with a level gauge. After the foundation cement is solidified, the pump shall be installed on the foundation and the base shall be corrected with a level gauge. The concentricity of the pump shaft and the motor shaft shall be strictly checked. The tolerance for excircle offset of the coupling shall be 0.1mm. The difference between the maximum and minimum clearance between the end faces of the two couplings shall not exceed 0.3mm.

3. The suction pipeline and the pressure-out pipeline of the pump should be supported. The weight of the pipeline is not allowed to be directly borne by the pump. Check whether the pipeline, instrument and other interfaces are sealed well.

Use of 2. pumps

1. Start

1) Prepare the necessary tools

2) Check the oil level in the oil storage chamber of the suspension body and control it at a position about 2mm from the center line of the oil level gauge.

3), check whether the rotation direction of the motor is consistent with the steering of the pump, it is strictly prohibited to reverse.

4), rotating the coupling by hand, should feel relaxed and uniform weight, and pay attention to identify whether there is friction in the pump and foreign body rolling noise, such as should try to exclude.

5), close the discharge pipe gate valve and the outlet pressure gauge, drain the air in the pump, so that the pump and the suction pipe are filled with liquid.

6) When the temperature of the conveying liquid is higher than 80 ℃, the pump should be evenly preheated, that is, the high temperature liquid conveyed is injected into the pump body, the cold water pipe and the leakage control cock of the sealing chamber are opened everywhere, and the flow and temperature are checked.

7) Start the motor (it is best to jog first to confirm that the pump rotates in the correct direction before it officially runs), open the inlet and outlet pressure gauges, then slowly open the outlet pipeline gate valve to the required position, and jump the leakage control cock of the sealing chamber to the appropriate position.

2-Operation

1), always check the temperature rise of the pump and motor, the temperature rise of the bearing should not be greater than 35 ℃, the limit temperature should not be greater than 75 ℃.

2) Pay attention to the change of the oil level in the oil storage chamber of the suspension body, and always control it within the specified range. In order to keep the oil clean and good lubrication, the new oil should be replaced regularly according to the actual situation of the site.

3), pay attention to the leakage of packing gland, to drip is appropriate.

4) In the process of operation, when abnormal sound or other faults are found, stop and check immediately, and continue to operate after troubleshooting.

5) Never allow the gate valve on the suction pipeline to adjust the flow to avoid steam turbidity.

3. Parking

1), slowly close the road gate valve, stop the motor.

2) Close the inlet and outlet pressure gauges and drain the liquid in the pump.

3) After the pump is cooled, close the cooling pipe switch.

4) When the pump is stopped for a long time, in addition to putting the liquid in the pump into the net, the pump must be cleaned, especially the sealing chamber must be washed carefully. It is best to remove the pump and reinstall it after cleaning. Coated with anti-rust oil, and the inlet of the pump is closed and kept properly.

-

1. The water pump does not absorb water; The pointer of the pressure gauge and vacuum gauge is beating violently. The reason is that the water injected into the water pump is not enough. The water pump or instrument leaks. Solution: Fill water into the water pump again; Tighten or block the leak.

2. The water pump does not absorb water, and the vacuum gauge shows a high degree of vacuum. The reason is: the water inlet pipe is not opened or blocked; The water absorption resistance is too large; The water absorption height is too large to exceed the allowable value. Solution: Check the water inlet pipe; Clean or replace the water absorption pipe; Reduce the water absorption height.

3. Look at the pressure at the outlet of the water pump of the pressure gauge, but the water pump still does not produce water. The reason is: the resistance of the outlet pipe is too large; the rotation direction is wrong; the impeller is blocked; the speed of the water pump is not enough. Solution: check or shorten the outlet pipe; Change the steering of the motor; Clean the impeller; increase the speed of the pump shaft.

4. The flow rate is lower than expected. The reason is: the water pump is blocked; The sealing ring is worn too much; The speed is not enough. Solution: clean the water pump and pipeline; Replace the sealing ring; Increase the speed of the water pump shaft.

5. The power consumed by the water pump is too high. The reason is: the packing gland is too tight; Impeller wear; The water supply of the water pump increases. Solution: Loosen the packing gland or take out the packing and square it; Replace the impeller; Adjust the gate valve to reduce the flow.

6. Abnormal sound occurred in the working process of the water pump, and the flow rate decreased until no water was produced. The early wear of the balancing device is due to: the gate valve is opened too much; The resistance of the suction pipe is too large; There is air infiltration at the suction place. The suction height is too high. Solution: Adjust the gate valve to reduce the flow rate; Check the suction pipeline; Check the bottom valve; Reduce the water absorption height; Tighten or block.

7, pump vibration, reason: pump shaft and motor axis is not on the same center line, solve: the pump and motor axis center line alignment.

8. Bearing overheating, reason: no oil or dirty oil; The water pump shaft and the motor shaft are not on the same center line. Solve: oil injection or oil change; Align the center line of the shaft.

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!