Recommend Products

Contact Us

| Email: | sales@sanchangpump.com |

| Hotline: | +86 133 0748 1676 |

| +86 193 1300 1794 | |

| Mobile: | +86 133 0748 1676 |

| Wechat: | +86 193 1300 1794 |

| Address: | No.517,Xiangfu Road |

| Yuhua District, | |

| Changsha City | |

| Hunan Province, P.R.C |

DFP Stainless Steel Self-balancing Multistage Centrifugal Pump

Classification:

DFP type self-balancing brine pump for salt mining

Key words:

water pump

Head range: 50~2000m

Conveying temperature: 0 ℃ ~ 80 ℃

Inlet pressure: allowable inlet pressure 0.6MPa

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

Hotline:

- Product Description

- Performance Parameter

- Installation Drawings

- Installation And Use

- Faults And Solutions

-

- Commodity name: DFP Stainless Steel Self-balancing Multistage Centrifugal Pump

Flow range: 3.75~1400 m3/h<br>Head range: 50~2000m<br>Conveying temperature: 0 ℃ ~ 80 ℃<br>Inlet pressure: allowable inlet pressure 0.6MPa<br>Sealing form: packing seal, mechanical seal<br>Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc</br></br></br></br></br>

Product Description

The equipment is used for water injection in the brine well of the brine extraction system. The flow medium of the brine extraction pump is salt-making wastewater, which contains a certain amount of salt (NaCl, Na2SO4, CaSO4). The temperature of the medium is generally normal temperature and does not exceed 50°C.

Product overview

DFP type self-balancing salt mining brine pump has good corrosion resistance and is suitable for conveying corrosive media. Self-balancing stainless steel multi-stage pump is developed and manufactured according to API610 standard and is in a leading position in technology in the industry. It has the advantages of wide high efficiency area, wide performance range, good cavitation performance, safe and stable operation, low noise, few wearing parts, and convenient installation and maintenance.

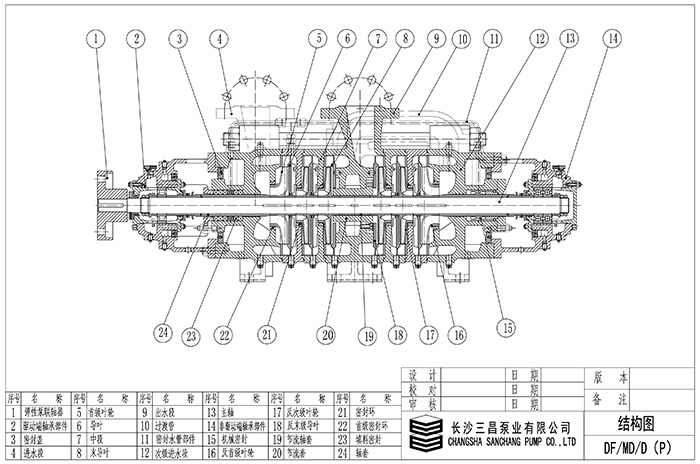

Structure Description

DFP type self-balancing salt mine halogen pump has no balancing device, I .e. no disc friction loss of balancing disc and no backflow loss of balancing water, so the pump efficiency is 5 ~ 14% higher than that of multi-stage pumps of the same category, and the shaft power of the pump is reduced without friction of balancing disc, thus achieving an energy-saving effect, so the power consumption of the pump during operation is about 3% higher than that of multi-stage pumps of the same category. At the same time, it completely solves various faults such as the wear of the balance disc and the balance ring or the rotor seizure caused by the failure of the balance device. Its design extends the service life of the pump. The trouble-free running time is more than 3 times that of ordinary pumps, and the maintenance cost of users is greatly reduced, thereby reducing the life cycle cost of the pump.

Use

No solid particles, the temperature of -20~105 ℃ corrosive liquid.

Pump model description

DF(P)46 - 50 X 8

DF(P)-horizontal self-balancing single suction stainless steel multistage centrifugal pump

46-The design point flow of the pump is 46m ³/h

50-The head of the design point of the pump is 50m.

8-The number of stages of the pump is 8

-

Flow range: 3.75~1400 m3/h

Head range: 50~2000m

Conveying temperature:-20-150 ℃ (please declare above 80 ℃)

Suction pressure: less than 0.6MPa

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

-

-

Self-balancing horizontal multi-stage pump installation to meet the general installation technical requirements, the installation should also pay attention to the following points:

1. When the motor and the water pump are installed in combination, the axial direction of the pump coupling end should be pulled out, and the gap value of 2-3mm end face should be left to ensure the axial gap value between the two couplings of the pump and the motor.

Note: Make sure that the bottom plate is leveled and the equipment level is good before grouting. In order for the installation to be successful, the coupling adjustment must be correct, and the flexible coupling cannot compensate for any obvious misalignment. The misalignment may cause rapid wear, noise, vibration and damage to the equipment. Therefore, the coupling is adjusted within the given limits. Effective measures must be taken to support the inlet and outlet pipes of the pump to prevent excessive load at the inlet and outlet of the pump.

2, self-balancing horizontal multi-stage pump and motor axis line should be in the same horizontal line.

The self-balancing horizontal multi-stage pump can only withstand its own internal force and cannot withstand any external force.

1. start:

Warning: For the safety of the operator, do not operate beyond the conditions of the pump nameplate, so as not to endanger the safety of equipment and operators. In order to ensure the smooth operation and maintenance of the pump and other actions, please refer to the instructions.

1. Before starting the pump, the rotor should be turned to inspect whether the rotor is flexible.

2. Check whether the motor steering is consistent with the pump steering.

3, close the pump outlet gate valve, pressure gauge cock, with the delivery of liquid or vacuum system to remove the air in the pipe and pump (no empty car operation).

4. Check the tightness of the connecting bolts between the pump and the motor and the safety conditions around the pump, so that the pump is ready to start.

5. Start the pump. After the pump is running normally, open the pressure gauge cock, slowly open the outlet gate valve, and control the pump lift given by the outlet pressure gauge reading.

2. run:

1. This type of pump relies on the internal balance mechanism to balance the axial force. The balance device has a balance liquid outflow, and the balance liquid is connected to the suction section by the balance water pipe.

2. The rolling bearings of this type of pump have cooling devices. The self-balancing horizontal multi-stage pump is maintained. The cooling water pipe must be connected before the water pump runs. The change of bearing temperature rise reflects the assembly quality of the pump. The bearing temperature rise shall not be 35 ℃, and the high temperature shall not be 75 ℃.

CAUTION: Operation of equipment that is not properly lubricated may cause bearing heating, breakage, pump blockage and equipment damage, self-balancing horizontal multistage pumps, and personal injury to the operator.

3. The rotor of this type of pump has certain axial movement during operation, and the clearance between the end faces of the two couplings of the motor and the water pump should be ensured.

4. During the operation of the pump, the impeller, sealing ring, guide vane sleeve, balance plate and shaft sleeve should be checked regularly for wear. If the wear amount is too large, it should be replaced in time.

5, use according to the specific situation to work out a more detailed operating procedures.

3. shutdown:

Before shutdown, the pressure gauge cock should be closed first, and then the outlet gate valve should be closed slowly. The self-balancing horizontal multi-stage pump can stop the motor only after the outlet gate valve is closed.

-

The pump cannot be started or the starting load is large:

Reason: It may be that the power is not connected, the motor is faulty, the impeller is loose or damaged, the circuit board is faulty, etc.

Solution: Check the power connection, replace the motor, replace the impeller or circuit board.

Insufficient or no pump flow:

Reason: It may be that the impeller or guide vane is worn or blocked, the sealing ring is worn or blocked, and the motor speed is insufficient.

Solution: replace the impeller or guide vane, remove the blockage, replace the sealing ring, check the motor and adjust the speed appropriately.

Insufficient or no pump head:

Reason: It may be that the impeller or guide vane is worn and blocked, the motor speed is insufficient, and the pipeline leaks.

Solution: replace the impeller or guide vane, remove the blockage, check the motor and adjust the speed appropriately, and repair the pipeline leak.

Pump vibration or noise is big:

Reason: It may be that the pump shaft is bent, the bearing is damaged, the impeller is unbalanced, and the pipeline is blocked.

Solution: correct the pump shaft, replace the bearing, balance the impeller, and remove the blockage in the pipeline.

Pump temperature too high:

Reason: may be bearing damage, insufficient lubrication, pump shaft bending, etc.

Solution: replace the bearing, increase the amount of lubricant, correct the pump shaft.

Pump leakage:

Reason: may be the seal ring wear or damage, pipe connection leakage.

Solution: replace the sealing ring and repair the leakage of the pipeline.

When solving the fault of the self-balancing horizontal multi-stage pump, we should first understand the cause of the fault, and then take the corresponding solution. If the above methods cannot solve the problem, it is recommended to seek the help of professional maintenance personnel. At the same time, in order to ensure the normal operation and service life of the self-balancing horizontal multi-stage pump, the pump should be inspected and maintained regularly to find and solve potential problems in time.

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!