Type D pumps can be classified according to structural characteristics as

Category: Water pump knowledge

2025-08-21

Type D pumps, widely used centrifugal pumps in the industrial field, are known for their high efficiency, stability, and reliability. These pumps come in various designs and structural features, capable of meeting fluid transport needs under different working conditions. Based on their structural characteristics, Type D pumps can be mainly divided into several categories, each with its unique applicable scenarios and advantages.

1. Single-stage Single-suction Type D Pump

The single-stage single-suction Type D pump is the most basic and common type. This pump features a simple structure and easy maintenance. Its impeller is located at one end of the pump shaft; fluid is drawn in from one side of the impeller and thrown out by the centrifugal force generated by the impeller's rotation, thus achieving fluid transport. Single-stage single-suction Type D pumps are usually suitable for low head and large flow conditions, such as urban water supply and farmland irrigation. Additionally, due to their compact structure and small footprint, they are often used in installation environments with limited space.

Structurally, single-stage single-suction Type D pumps typically use horizontal installation. The pump body, pump cover, and shaft seal device form a sealed chamber that effectively prevents fluid leakage. The shaft seal part mostly uses mechanical seals or packing seals to ensure long-term stable operation of the pump. Meanwhile, to meet the transport needs of different media, the pump body material can be selected from cast iron, stainless steel, and other materials, enhancing the pump's corrosion resistance and service life.

2. Multistage Type D Pump

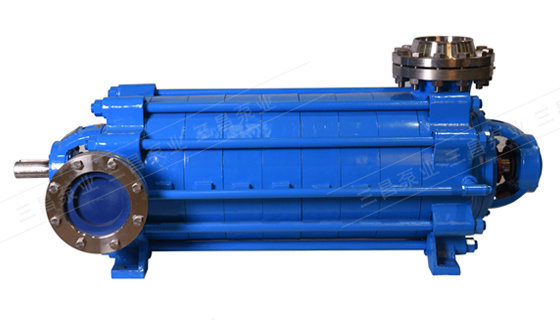

Multistage Type D pumps, as the name suggests, consist of multiple single-stage pumps connected in series, with each stage providing a certain head to the fluid. These pumps are characterized by high head and are suitable for scenarios requiring long-distance transport or overcoming large resistance, such as water supply for high-rise buildings and mine drainage. The design of multistage Type D pumps allows them to maintain high efficiency while providing a wider range of head, meeting fluid transport needs under complex working conditions.

Structurally, multistage Type D pumps usually adopt vertical or horizontal installation. The pump shaft passes through multiple impellers, with guide vanes or intermediate sections between each impeller to guide fluid flow smoothly and reduce energy loss. Additionally, multistage pumps are equipped with balancing devices to balance axial forces, reduce bearing wear, and improve operational stability. The shaft seal part also uses advanced mechanical seal technology to ensure high sealing performance.

3. Sectional Type D Pump

Sectional Type D pumps are specially designed pumps whose pump body and pump cover are divided into several sections along the axial direction, connected by flanges between each section. This design makes disassembly and assembly more convenient, facilitating maintenance and replacement of parts. This is especially important when handling large pumps or special media. Sectional Type D pumps are widely used in industries such as petroleum, chemical, and power, for transporting high-temperature, high-pressure, and highly corrosive fluids.

Structurally, sectional Type D pumps not only inherit the advantages of single-stage and multistage pumps but also improve pump flexibility and adaptability through modular design. High-strength bolts are used to fasten each section, ensuring the overall strength and sealing of the pump body. At the same time, for specific media, the interior of the pump body can undergo special treatments, such as rubber lining or spraying wear-resistant alloys, to enhance corrosion resistance and wear resistance.

4. Other Special Structure Type D Pumps

In addition to the above common Type D pumps, there are some special structure Type D pumps, such as self-priming Type D pumps, corrosion-resistant Type D pumps, and high-speed Type D pumps. These pump types are designed according to specific application needs and have unique structural and performance characteristics. For example, self-priming Type D pumps can automatically draw water without priming, suitable for unstable water sources or frequent start-up conditions; corrosion-resistant Type D pumps use special materials and surface treatment processes, suitable for transporting highly corrosive media; high-speed Type D pumps increase flow and head by raising rotational speed, suitable for high-precision control systems requiring efficient transport of small flow rates.

In summary, Type D pumps can be classified into single-stage single-suction, multistage, sectional, and other special structure types based on structural characteristics. Each type has its unique applicable scenarios and advantages. Users should comprehensively consider factors such as pump flow, head, media characteristics, and installation conditions according to specific working conditions to ensure the selected pump type meets actual usage requirements and achieves efficient, stable, and reliable fluid transport.

RELATED INFORMATION

2025/08/22

2025/08/21

Recommend Products

Contact Us

Free Hotline:0086-13307481676

Fixed telephone:0086-13307481676

Mobile:0086-13307481676(WeChat)

E-mail:sales@sanchangpump.com