Recommend Products

Contact Us

| Email: | sales@sanchangpump.com |

| Hotline: | +86 133 0748 1676 |

| +86 193 1300 1794 | |

| Mobile: | +86 133 0748 1676 |

| Wechat: | +86 193 1300 1794 |

| Address: | No.517,Xiangfu Road |

| Yuhua District, | |

| Changsha City | |

| Hunan Province, P.R.C |

MD type wear-resistant multistage centrifugal pump for mine

Classification:

BB4 Multistage Centrifugal Pump

MD type wear-resistant multistage centrifugal pump for mine

Mining industry

Multi-stage pump for mine

MD type wear-resistant multistage centrifugal pump for mine

Key words:

water pump

Head range: 50~2000m

Conveying temperature: 0 ℃ ~ 80 ℃

Inlet pressure: allowable inlet pressure 0.6MPa

Sealing form: packing seal, mechanical seal

Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc

Hotline:

- Product Description

- Performance Parameter

- Installation Drawings

- Installation And Use

- Faults And Solutions

-

- Commodity name: MD type wear-resistant multistage centrifugal pump for mine

Flow range: 3.75~1400 m3/h<br>Head range: 50~2000m<br>Conveying temperature: 0 ℃ ~ 80 ℃<br>Inlet pressure: allowable inlet pressure 0.6MPa<br>Sealing form: packing seal, mechanical seal<br>Water pump material: HT200, HT250, QT600, ZG, 304, 316, 316L, 317L, 904L, CD4-MCu, etc</br></br></br></br></br>

MD-type mine wear-resistant multistage centrifugal pump is a horizontal single-suction multistage segmented centrifugal pump, the use of high-efficiency energy-saving products of the hydraulic model, research and development of high-efficiency high-pressure multistage centrifugal pump dedicated to the mining industry. It has the advantages of high efficiency, wide performance range, safe and stable operation, low noise, long life, convenient installation and maintenance, etc. This type of mine multistage centrifugal pump is used for conveying neutral mine water with solid particle content ≤ 15%, neutral mine water with particle size ≤ 0.5mm and temperature ≤ 80C and similar other sewage. Suitable for steel plant, mine drainage, sewage transportation and other occasions.

Model description:

MD280-43 × 5;

MD-multistage centrifugal pump for mine;

280-indicates the flow rate of the pump (m3/h);

43-indicates the single-stage head of the pump (m);

5-indicates series.

Direction of rotation:

Clockwise rotation as viewed from the motor end to the pump.

Material of main parts:

Pump flow parts are made of wear-resistant ductile iron, cast steel and stainless steel (304, 316, 316L, 2205, 2507, etc.).

Scope of package:

The pump is supplied with motor and base, and can be equipped with functional base or its own base. The manufacturer also provides accessories (including discharge cone pipe, gate valve, bottom valve and check valve) and spare parts (including impeller, sealing ring, guide vane sleeve, balance plate and shaft sleeve).

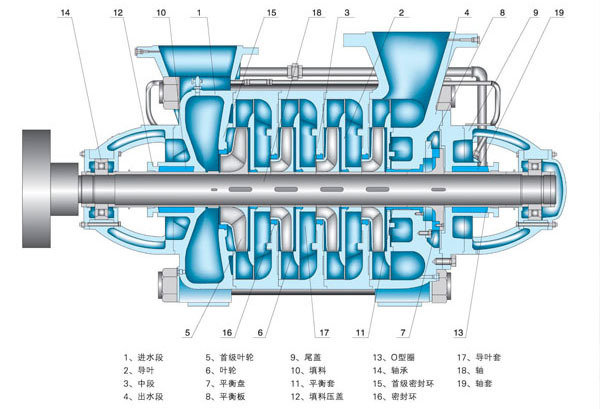

Structure description:

D, DG, MD, DF, DY pumps are mainly composed of fixed parts, rotor parts, bearings and shaft seals.

1. Partial stator

It is mainly composed of water inlet section, middle section, water outlet section and guide vane, etc., and each section is tightened with a bar to form a working room. The inlet of D-type multistage pump is horizontal and the outlet is vertical upward. DG pump inlet and outlet are both vertically upward. MD, DF and DY pumps have their outlets vertically upward and their inlets are generally horizontal. As required, they can also be produced in the vertical upward direction.

2. Rotor part

It is mainly composed of shaft, impeller, balance plate and shaft sleeve. The shaft transmits power to the impeller to make it work; the balance disc is used to balance the axial force; the shaft is equipped with a replaceable sleeve to protect the shaft.

3. Bearing part

It is mainly composed of bearing body, bearing and bearing gland. In addition to 85-67, 155-67, 600-60 type pump using sliding bearings, thin oil lubrication, the rest of the pump are used rolling bearings, grease lubrication. 85-67, 155-67 can also use rolling bearing structure.

4. Shaft seal

Generally, soft packing is used for sealing, which is mainly composed of sealing body, packing and water retaining ring on water inlet section and tail cover. There is a constant pressure of water in the sealing cavity, which plays the role of water seal, water cooling and lubrication. D type pump water seal generally comes from the high pressure water in the pump, DG, MD, DF, DY type pump comes from the pressure water in the pump or external water supply. DG, MD, DF, DY type pump more mechanical seal.

5. Transmission

The pump is directly driven by the prime mover through an elastic coupling. From the prime mover end, the pump rotates clockwise.

-

流量范围:3.75~1100m3/h

扬程范围:50~1800m

输送温度:0℃~80℃

进口压力:允许进口压力0.6MPa

密封形式:填料密封、机械密封

水泵材质:HT200、HT250、QT600、ZG、304、316、316L、317L、904L、CD4-MCu等

-

-

一、安装前准备工作

1.确定多级泵的安装位置:应选择安装稳固、便于操作、维修和检修的地点。

2.确认注水口位置:注水口应设置在进口压力管道处,并距泵20cm左右,避免回流使多级泵叶轮转速产生变化。

3.处理进口压力管道:准备好管道及法兰连接部分,确保连接部分无异物或锈蚀。

4.准备好电源和电缆:根据多级泵的电源要求选择合适的电缆,并确保电缆质量良好。

二、安装步骤

1.组装各部件:按照说明书或图纸的要求组装各部件,确定排水口、放气口、润滑部件等位置。

2.安装多级泵:将多级泵置于安装位置,注意多级泵底座与地面接触平稳,底座座面垂直于地面。

3.接口连接:连接进口压力管道和出口压力管道,连接法兰要求平行、水平,且未扭曲和变形。

4.电缆接线:根据多级泵电气连接图接线,注重接线的标准化与合理布线。

5.注水灌引:打开多级泵进口压力管道的截止阀门,将清洁的水(或包涵添加泵灌引液)灌引进泵内,避免泵振动产生异响。

6.对泵进行调整:调整变频器或按需减速器,保证多级泵的电机正常工作,水流速度适中。

三、安装后检查

1.检查泵的整体安装:保证多级泵的底座平稳垂直。

2.检查各管道连接:确认各接口处是否连接紧密,是否有异响等异常情况。

3.泵的运动测试:开启电源,检查电机转动是否平稳、声音是否正常,泵是否产生漏水等现象。

4.系统压力测试:实验中,智能仪表记录控制阀门打开关闭状态及水流量等数据。测试过程中,关注系统周围是否产生噪声、振动或温度过高等异常情况,如有异常,及时处理。

5.检查电线:确认电线是否正确接线、无损伤等相关细节是否符合安装规范。

以上是多级泵的安装步骤详解,希望读者可以按照上述步骤正确安装多级泵,确保安装后的多级泵能够正常运行,为生产和生活提供更好的保障。

-

故障一:多级泵不吸水压力表和真空表指针剧烈跳动

原因:1.灌注引水不够 2.管路与仪表联接处漏气 3.吸程过高

解决方法:1.检查底阀是否漏水.再雇足引水 2.拧紧漏气处 3.降低吸水高度

故障二:多级泵不吸水真空表表示高度真空

原因:1.底阀没有打开或己堵塞 2.吸水管路阻力太大 3.过滤器堵塞

解决办法:1.检査底阀 2.更换吸水 3.清理过滤器

故障三:压力表有压力但仍不出水

原因:1.出水管阻力太大 2.旋转方向不对 3.出口管阀门未开 4.叶轮堵塞

解决方法:1.检査或缗短水管 2.检査电机.两相互调 3.打开出口阀 4.清除叶轮内的污物

故障四:达不到设计流量

原因:1.有空气吸入 2.由于水位降低.淹没深度不够 3.叶轮内有异物堵塞 4.转子部分严重磨损

解决方法:1.检査漏气部位并排除 2.延长吸水管.加深淹深度 3.拆卸并滴除异物 4.更换密封环

故障五:多级泵消耗功率过大

原因:1.填料压得过紧.并发热 2.流置过大 3.回转体与壳体有碰擦 4.泵轴承磨损 5.泵轴弯曲

解决方法:1.适当放松填料压力 2.关小闸阀开度 3.修整回转体与壳体位置 4.更换轴承 5.更换或校正

故障六:多级泵振动加大

原因:1.叶轮局部有堵塞 2.叶轮破损 3.流量过小 4.泵轴与电动机不同心 5.轴承破损 6.混入空气.发生汽蚀

解决方法:1.拆卸清除异物 2.更换叶轮 3.稍开出口阀 4.定点找正 5.改变吸入位.改善吸水

Previous Page

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!