Where is the balance pipe of the centrifugal pump located?

Category: Water pump knowledge

2025-08-22

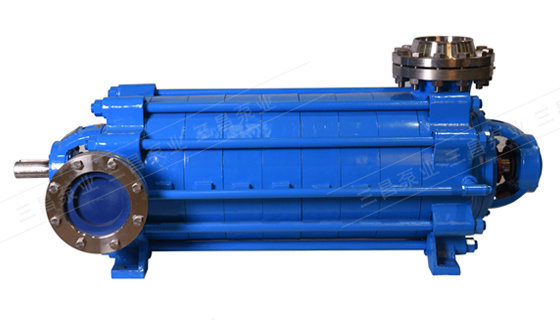

As a widely used fluid conveying device in industry, agriculture, municipal engineering, and daily life, the stability and reliability of centrifugal pump performance are crucial. In the structural design of centrifugal pumps, the balance pipe, as an important component for balancing axial force, plays a vital role.

1. Basic Structure of Centrifugal Pumps and Axial Force Issues

The basic structure of a centrifugal pump mainly consists of the impeller, pump body (pump casing), pump shaft, bearings, sealing rings, and packing box. Among these, the impeller is the core component of the centrifugal pump, responsible for transferring mechanical energy to the fluid, giving it kinetic and static pressure energy. However, during the operation of the centrifugal pump, due to the fluid acting on the impeller, an axial force directed toward the pump inlet is generated. This axial force pushes the rotor toward the suction side, which in severe cases may cause friction or collision between the impeller and the pump casing, affecting the safe operation of the pump.

2. Position and Function of the Balance Pipe

To solve the axial force problem, a balance pipe is introduced in the design of centrifugal pumps. The balance pipe is usually located on the high-pressure side near the hub outside the impeller disk and is connected to the suction end of the centrifugal pump. Specifically, the balance pipe extends from the pump's outlet sealing ring and is routed through an external pipe to the pump's inlet end. Its main function is to balance the axial thrust of the pump, reduce the axial movement of the rotor, and prevent friction between the impeller and the casing.

When the pump is operating, high-pressure water is discharged from the impeller outlet, with part flowing to the back of the impeller, making the pressure behind the impeller basically equal to that at the outlet. The front side of the impeller is the suction end, where the pressure is very low. Thus, a large pressure difference is generated on both sides of the impeller, producing axial thrust. The role of the balance pipe is to direct the pressure water behind the impeller to the inlet side, balancing the pressure on both sides of the impeller and thereby eliminating or reducing the axial thrust.

3. Balancing Principle and Effect of the Balance Pipe

The balancing principle of the balance pipe lies in introducing liquid from the high-pressure end to the low-pressure end to balance the pressure difference on both sides of the impeller, thereby balancing the axial force. However, it should be noted that the balance pipe cannot completely balance the axial force. The remaining axial force must be borne by specially installed thrust bearings. Additionally, the use of the balance pipe can cause liquid backflow, reducing the pump's efficiency. Nevertheless, due to its simple structure and ease of implementation, the balance pipe is still widely used in centrifugal pump design.

4. Other Methods for Balancing Axial Force in Centrifugal Pumps

Besides the balance pipe, there are various methods to balance the axial force in centrifugal pumps, including:

1. Balance Holes on the Impeller

Several small holes (called balance holes) are symmetrically drilled near the hub on the impeller disk, and sealing rings are set on the pump casing and impeller disk to reduce the pressure difference of the liquid on both sides of the impeller, thereby reducing axial force. This method is commonly used in single-stage, single-suction centrifugal pumps.

2. Using Double-Suction Impellers

Double-suction impellers, being symmetrical on both sides, theoretically do not generate axial force. However, due to manufacturing quality and differences in fluid flow on both sides of the impeller, it is impossible to completely balance the axial force.

3. Using Balanced Impellers

Radial ribs are set on the outside of the impeller disk to balance axial force. After setting the radial ribs, the liquid on the high-pressure side inside the impeller is driven to rotate by the ribs, and under centrifugal force, the pressure of the liquid in this cavity decreases, thus balancing the axial force on both sides of the impeller.

4. Installing Thrust Bearings

For small pumps with low axial force, thrust ball bearings are often used to balance the axial force. However, the installation of radial thrust bearings has directional requirements; if installed incorrectly, they will not balance the axial force and may even cause accidents.

5. Balancing Methods for Multistage Centrifugal Pumps

Multistage centrifugal pumps usually use balance disks, balance drums, or combined devices to balance axial force. These methods are relatively complex but more effective.

In summary, the balance pipe of a centrifugal pump is located between the high-pressure side near the hub outside the impeller disk and the suction end of the centrifugal pump. Its main function is to balance the axial thrust of the pump and prevent friction between the impeller and the casing. Although the balance pipe cannot completely balance the axial force and may cause liquid backflow reducing efficiency, its simple structure and ease of implementation make it significant in centrifugal pump design. At the same time, depending on the specific type and operating conditions of the centrifugal pump, other methods for balancing axial force can be selected to ensure the safe and stable operation of the pump.

RELATED INFORMATION

2025/08/22

2025/08/21

Recommend Products

Contact Us

Free Hotline:0086-13307481676

Fixed telephone:0086-13307481676

Mobile:0086-13307481676(WeChat)

E-mail:sales@sanchangpump.com