Testing Center

(1) Main Testing Processing Equipment List

|

Serial Number |

Name |

Specifications and models |

Quantity |

Unit |

Manufacturer/place of origin |

Usage |

|

1 |

vertical lathe |

CX5116D |

2 |

Taiwan |

Dalian Jirun Group Dalian Watt Heavy Machine Tool Co., Ltd. |

In use |

|

2 |

Digital display horizontal boring and milling machine |

TX6111D |

2 |

Taiwan |

Shenji Group Kunming Machine Tool Co., Ltd. |

In use |

|

3 |

horizontal lathe |

CW6163P |

2 |

Taiwan |

Yunnan Machine Tool/Yunnan |

In use |

|

4 |

horizontal lathe |

CW6150B/A |

4 |

Taiwan |

Shenyang Machine Tool/Shenyang |

In use |

|

5 |

horizontal lathe |

CS6140 |

5 |

Taiwan |

Baoji Machine Tool/Baoji |

In use |

|

6 |

horizontal lathe |

CA6140A |

3 |

Taiwan |

Shenyang One Machine/Shenyang |

In use |

|

7 |

horizontal lathe |

CW6163B |

4 |

Taiwan |

Shenyang Machine Tool/Shenyang |

In use |

|

8 |

CY horizontal metal band saw machine |

|

2 |

Taiwan |

Zhejiang Weiye/Zhejiang |

In use |

|

9 |

horizontal lifting table milling machine |

XW6036A |

3 |

Taiwan |

Tengzhou Daheng Machine Tool/Tengzhou |

In use |

|

10 |

cylindrical grinder |

M1332BX |

4 |

Taiwan |

Shanghai Machine Tool Works/Shanghai |

In use |

|

11 |

radial drilling machine |

Z3050X |

3 |

Taiwan |

Shenyang Machine Tool/Shenyang |

In use |

|

12 |

argon arc welding machine |

WS250S |

4 |

Taiwan |

TA/OR General/Shanghai |

In use |

|

13 |

Dynamic balancing machine |

YYW-1600A |

1 |

Taiwan |

Jinan Silver Arrow CNC equipment/Jinan |

In use |

|

14 |

Digital display hydraulic strength testing machine |

SWY |

2 |

Taiwan |

Wuxi Sanfeng Instrument/Wuxi |

In use |

|

15 |

electromagnetic flowmeter |

DN50/6.3MPa |

2 |

Taiwan |

Central Tianyi/Central |

In use |

|

16 |

electromagnetic flowmeter |

DN80/10.0MPa |

2 |

Taiwan |

Kaifeng instrument/Kaifeng |

In use |

|

17 |

electromagnetic flowmeter |

DN100/10.0MPa |

2 |

Taiwan |

Kaifeng instrument/Kaifeng |

In use |

|

18 |

electromagnetic flowmeter |

DN150/16.0MPa |

2 |

Taiwan |

Kaifeng instrument/Kaifeng |

In use |

|

19 |

electromagnetic flowmeter |

DN200/10.0MPa |

2 |

Taiwan |

Kaifeng instrument/Kaifeng |

In use |

|

20 |

electromagnetic flowmeter |

DN250/10.0MPa |

2 |

Taiwan |

Kaifeng instrument/Kaifeng |

In use |

|

21 |

electromagnetic flowmeter |

DN300/6.3MPa |

2 |

Taiwan |

Kaifeng instrument/Kaifeng |

In use |

|

22 |

vibrometer |

AR63A |

1 |

Taiwan |

ARCO Hong Kong Henggao Electronics Group/Hong Kong |

In use |

|

23 |

Richter hardness tester |

MH180 |

1 |

Taiwan |

Beijing Meitaike Technology/Beijing |

In use |

|

24 |

Large metallographic examination instrument |

601 |

1 |

Taiwan |

Shanghai BiMu Instrument/Shanghai |

In use |

|

25 |

precision sound level meter |

JS-1 |

1 |

Taiwan |

Jiaxing Hengsheng Electronics/Jiaxing |

In use |

|

26 |

ultrasonic flaw detector |

MUT600B |

2 |

Taiwan |

Beijing Mattel Technology/Beijing |

In use |

|

27 |

Torque meter |

0-1000N.m |

1 |

Taiwan |

Jinan Fen Test Instrument/Jinan |

In use |

|

28 |

Torque meter |

0-2000N.m |

1 |

Taiwan |

Jinan Fen Test Instrument/Jinan |

In use |

|

29 |

Torque meter |

0-5000N.m |

1 |

Taiwan |

Jinan Fen Test Instrument/Jinan |

In use |

|

30 |

Torque meter |

0-10000N.m |

1 |

Taiwan |

Jinan Fen Test Instrument/Jinan |

In use |

(2)Company water pump comprehensive test bench

|

|

|

|

|

|

|

|

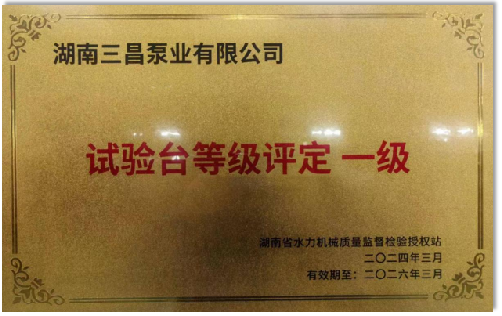

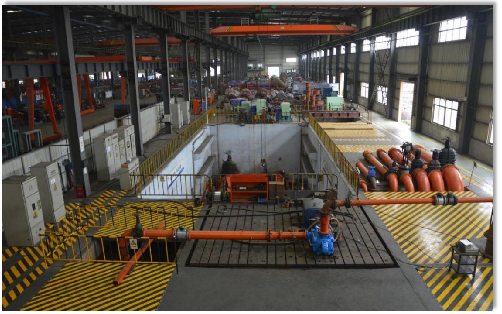

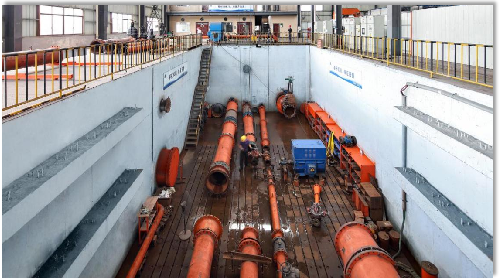

In accordance with the relevant standards, each pump factory before the whole machine to do full-speed performance test, and to do full-speed operation reliability test, the company has a national.Level 1 test center. The test can lift 50 tons of crane, the maximum lifting height of 12 meters. The test pool is 8000 cubic meters with a depth of 12 meters. The test center is advanced and complete. Automatic acquisition and processing of test data, with self-test, test error analysis and other functions. Maximum measurable power up to 2500KW. At the same time, it is equipped with advanced test instruments, pressure measurement adopts advanced pressure sensor and precision pressure gauge, flow measurement adopts high-precision electromagnetic flowmeter, power measurement adopts high-precision torque and speed sensor, and is equipped with infrared thermometer, vibration meter, sound level meter, hand-held tachometer and other advanced measuring equipment. Can complete the centrifugal pump performance, mechanical operation test and cavitation, vibration, noise and other tests.

|

|

|

|

|

|

4)multistage centrifugal pumpTest:

1. Instrument

Pressure sensor: Beijing GuanchengThe accuracy is ± 0.25%;

Electromagnetic flowmeter: Shanghai Kelon Accuracy is 0.3 percent.

Power: digital power meterThe accuracy is 0.5

Speed: Monado, United StatesACT-3 type tachometer, accuracy class 0.1

Accuracy class of open test benchClass I (flow error 2.0%; speed 0.5%; lift 1.5%; power 2.0%; efficiency 2.9%)

2. Develop test outline

Formulation before pump testDevelop test outline

1)、Test outline in accordance with national standardsGB/T3216-2005 "Rotary power pump hydraulic performance acceptance test level 1 and 2" specified in the level 2 requirements for horizontalmultistage centrifugal pumpThe relevant details of the factory test are specified.

2)、Suitable for horizontalmultistage centrifugal pumpFactory performance test.

3)、as horizontalmultistage centrifugal pumpDelivery testReportbasis.

4)、Water pump performance guarantee value

According to the pump performance guarantee value provided by the manufacturer, the test and examination shall be carried out, and the performance guarantee value shall meet the national standard.GB/T3216-2005 "Rotary Power Pump Hydraulic Performance Acceptance Test Level 1 and Level 2" specified in the second standard requirements, meet the requirements for qualified products, otherwise it is unqualified.

4)Executive standard

The manufacturing, packaging, transportation, storage, testing, acceptance and commissioning of the bidding main drainage equipment shall comply with the latest national regulations, specifications and manufacturing standards, including but not limited:

1. Coal Mine Safety Regulations 2022 Edition

2. Code for Design of Mine in Coal Industry GB 50215-2015

3. Code for Design of Coal Mine Underground Drainage Pumping Station and Drainage Pipeline GB 50451-2017

4. Multistage Centrifugal Pump for Coal Mine MT/T114-2005

5.《Technical conditions for centrifugal pump(Class III)》 GB/T 5657-2013

6. Centrifugal pumps, mixed flow pumps and axial flow pumps NPSH GB/T 13006-2013

7.《Centrifugal pump Efficiency》 GB/T 13007-2011

8. Rotary power pump GB/T 3216-2016

9. Measurement and Evaluation Method of Pump VibrationGB/T 29531-2013

10. Noise measurement and evaluation method of pumpGB/T 29529-2013

11. Determination of water pump flow GB/T 3214-2007

12. Mechanical Vibration GB/T 9239-2006

13.《alloy structural steel》 GB/T 3077-2015

14. Carbon Structural Steel GB/T 700-2006

15. Ductile Iron Castings GB/T 1348-2019

16. Corrosion-resistant Steel Castings for General Purpose GB/T 2100-2017

17. Steel pipe flanges-Part 1: PN Series GB/T 9124.1-2019

18. Grey Iron Castings for Pumps JB/T 6880.1-2013

19. Steel Castings for Pumps (JB/T 6880.2-2021)

20. Technical Conditions for Painting of Pump Products (JB/T 4297-2021)

21. Dimension Tolerance Parts for Overflow Parts of Centrifugal Pump Castings JB/T 6879-2021

22. Integral Steel Pipe Flanges JB/T 79-2015

23. Measurement, Evaluation and Limits of Mechanical Vibration of Motors with Shaft Center Height of 56mm and Above GB/T 10068-2020

24. Measurement Methods and Limits for Noise of Rotating Electrical Machines GB/T 10069-2008

25. Basic Series Technical Conditions for Large Three-phase Asynchronous Motors GB/T 13957-2008

Test Method for Three-phase Asynchronous Motor GB/T 1032-2012

27. Cooling Mode of Rotating Motor GB/T 1993-1993

28. Rates and Performance of Rotating Electrical Machines (GB/T 755-2019)

29. Explosive Atmospheres Part 1 GB 3836.1-2021

Explosive Atmospheres Part 2 GB 3836.2-2021

31. Classification of the protection degree (IP code) of the overall structure of rotating electrical machines GB/T 4942.1

32. Code of Motor Structure and Installation Form GB/T 997-2003

33. General Technical Conditions for Packaging of Mechanical and Electrical Products GBT 13384-2008

34. pictorial signs for packaging, storage and transportation GB/T191-2016

35. Identification of Safety Marks for Mining Products AQ 1043-2007

36. Standard for Examination and Acceptance of Coal Mine Safety Facilities AQ1055-2008

5)Packaging, transportation and protection measures

1、PressProvisions of GB/T13384 standardRight.PumpGroup conductedPackaging, and take rain, moisture, rust, shock and other measures,AvoidPump during transport due to vibration and impactCause pump unitdamage.

2. Before the equipment is shippedEnsure that the pump unit is dry and moisture-proof.

3. All openings, flanges and joints shall be protected to prevent corrosion, damage and entry of debris during transportation and storage. The inlet and outlet of the pump and the pipe hole are closed with a cover plate.

4. The threaded hole or the welding hole of the pipe socket that needs to be connected on site shall be protected by thread or other means.

5. Coverings, metal straps or fasteners are not welded to the equipment.

6. Spare parts and wearing parts are packaged separately,There are obvious signs.

7. If the topcoat is found to be damaged after being transported to the site, the topcoat shall be repainted free of charge or sufficient paint shall be provided.

8. Storage conditions

The buyer needs to know:

Storage siteThe storage site of spare parts must be ventilated, ventilated, lit and clean, keep air circulation during the day, and close the doors and windows in rainy days to ensure that the spare parts are dry and prevent moisture.

- method of custody

The buyer needs to know:

1, storage should abide by the three principles: fire prevention, waterproof, anti-pressure; Fixed point, quantitative; First in, first out.

2. When the spare parts are stacked up and down, "the top is small and the bottom is big, the top is light and the bottom is heavy".

3, easy to damp spare parts, it is strictly prohibited to place directly on the ground, should be placed on the shelf or pallet for isolation.

4, metal spare parts need to be regularly rust, rubber products do not contact with oil,Grease. All spare parts shall be dust-proof.

10、Expected storage period

The buyer needs to know:

1. The expected effective storage period of spare parts such as O-rings is not less1Year.

2, shaft sleeves and other spare parts in the storage conditions, storage methods appropriate premise, can be long-term.Save.